Architects: Want to have your project featured? Showcase your work through Architizer and sign up for our inspirational newsletters.

Hybrid construction materials and techniques might be the beacon of hope in a construction industry riddled with carbon-intensive practices and logistical challenges. The development of hybrid technologies is not merely a response to the demands of modern construction; it’s a visionary leap forward fueled by urgent environmental concerns and the pressing need for sustainable solutions. Traditional construction methods and materials fall short of meeting the rigorous standards of eco-consciousness. With ecological degradation looming large, we must change how we build and minimize our carbon footprint.

Hybrid construction materials and techniques offer an alternative approach to traditional and modern building materials and methods. Combining the strengths of different materials, such as earth, stone, timber, steel, concrete and composite materials, on the one hand, and merging the timeless effectiveness of traditional craftsmanship with modern technology, on the other hand, can improve the structural performance, durability and sustainability of contemporary building projects.

Hybrid Technologies: Leading the Charge for Sustainable Construction

Morocco Pavilion Expo Dubai 2020 by OUALALOU+CHOI. Dubai, United Arab Emirates | Photo by Boegly + Grazia photographers

Merging traditional materials such as wood, stone, and earth with innovative technologies has paved the way for creating components that define hybrid construction. This integration leverages the natural strengths and aesthetic appeal of traditional materials while enhancing them with properties through modern engineering techniques. For example, wood, a renewable and versatile resource, is transformed into engineered products like cross-laminated timber (CLT) and glue-laminated timber (glulam). These engineered wood products offer superior strength, stability and durability, making them suitable for large-scale construction projects that traditional timber could not support.

Earth, used in adobe and rammed earth construction, has seen a resurgence in hybrid construction through the development of compressed earth blocks (CEBs). Stone can be combined with advanced cutting and shaping technologies to create prefabricated panels that are easier to install and provide better thermal performance. Innovations in masonry have also introduced techniques to reinforce stone structures with modern materials, increasing their load-bearing capacity and longevity.

Preserving Heritage Through Hybrid Construction

Using locally sourced raw materials to create hybrid construction byproducts is a sustainable approach. Not only does it reduce environmental impact, but it also reflects the unique characteristics of a region, celebrating the cultural heritage and craftsmanship of communities while meeting modern construction standards.

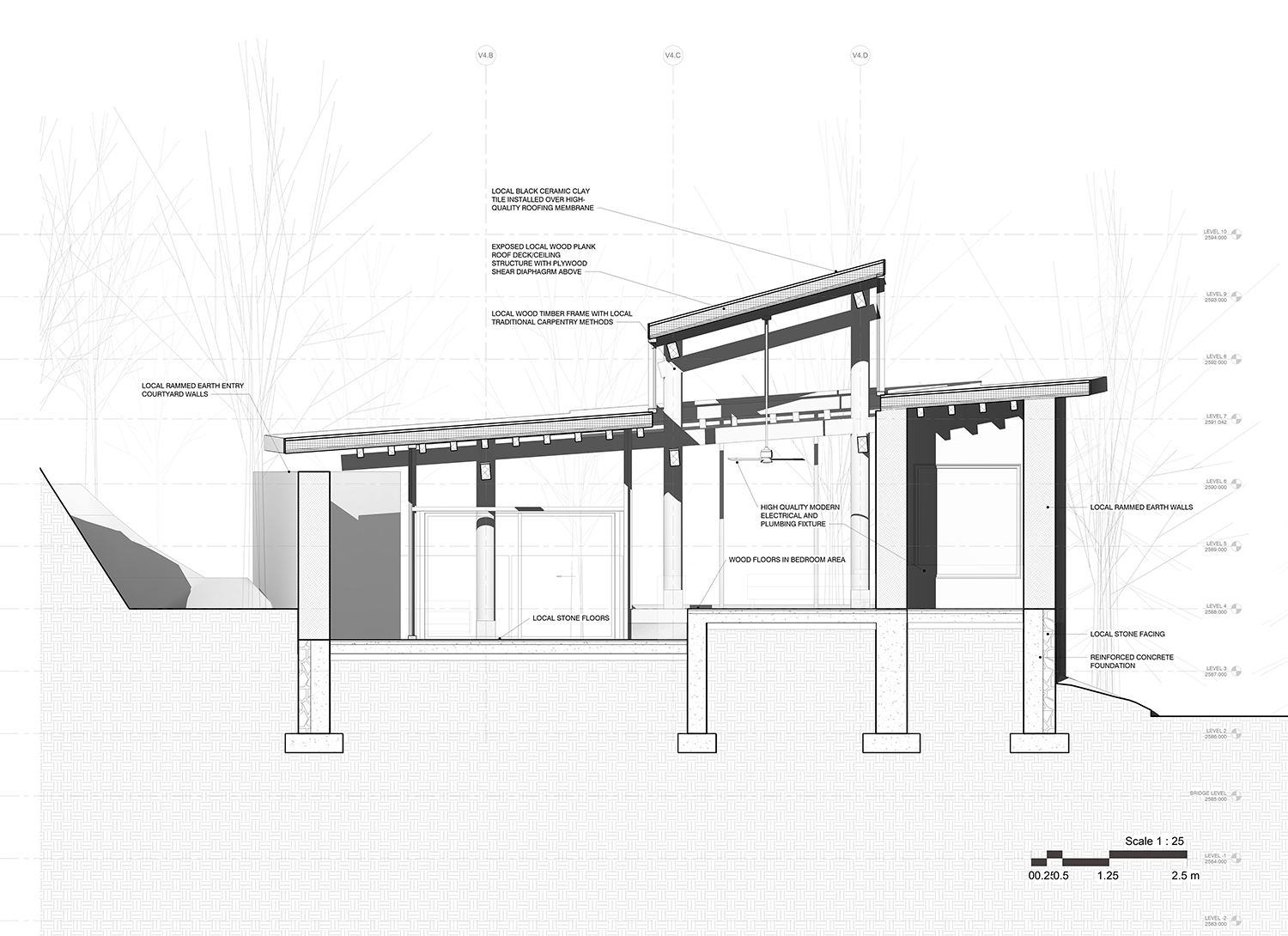

The Linden Centre Shaxi Community Campus by Anderson Anderson Architecture and Atelier FUN. Yunnan, China | Photo by Zhang Yangyang.

The Linden Centre Shaxi Community Campus. Building section. | Drawing courtesy of Anderson Anderson Architecture and Atelier FUN.

The Linden Centre Shaxi Community Campus is an outstanding example of buildings that blend locally sourced materials and craftsmanship with hybrid byproducts and building techniques. The project, funded by the Poverty Reduction Program for Rural China and The Linden Centre, a cultural education program, creates new educational and economic opportunities, such as teaching building skills to a community that has largely preserved its rich craft and cultural traditions. For centuries, the men and women of the region have built their community with stone foundations, rammed earth walls, timber frames, and tiled roofs. The new project, which continues this tradition using local labor and materials, also includes modern elements like advanced glazing, reinforced concrete and manufactured fittings to meet international standards.

Timber, Concrete and Steel: The Perfect Hybrid for Modern Architecture

The combination of timber with concrete and steel is gaining popularity in hybrid construction due to the search for more sustainable structural systems and innovative potential. Timber’s environmental benefits as a renewable resource with a smaller carbon footprint are key factors driving this trend. Advancements in engineered wood products like cross-laminated timber (CLT) and glue-laminated timber (glulam) have improved timber’s strength and durability, making timber suitable for larger structures traditionally dominated by concrete and steel. Additionally, timber systems in hybrid construction offer exceptional thermal performance and material efficiency, contributing to sustainability by reducing energy consumption and waste. Regulatory changes in many countries now allow for taller wood buildings, further encouraging its use.

United Nations International Organization for Migration by Sharon Davis Design, Geneva, Switzerland.

The United Nations International Organization for Migration project prioritizes sustainable materials and user well-being. The design minimizes the use of materials with high carbon footprints. Instead, it utilizes a hybrid structural system consisting of a cross-laminated timber (CLT) frame resting above a pediment of rammed earth. This approach creates a building with a localized construction footprint by taking advantage of materials found on-site and nearby CLT mills in Switzerland and Germany. Additionally, recycled aggregate from the existing office building’s demolition is used in areas where more carbon-intensive materials such as concrete are required, further reducing environmental impact.

The Synergy of Hybrid Construction and Prefabrication: Efficiency and Innovation

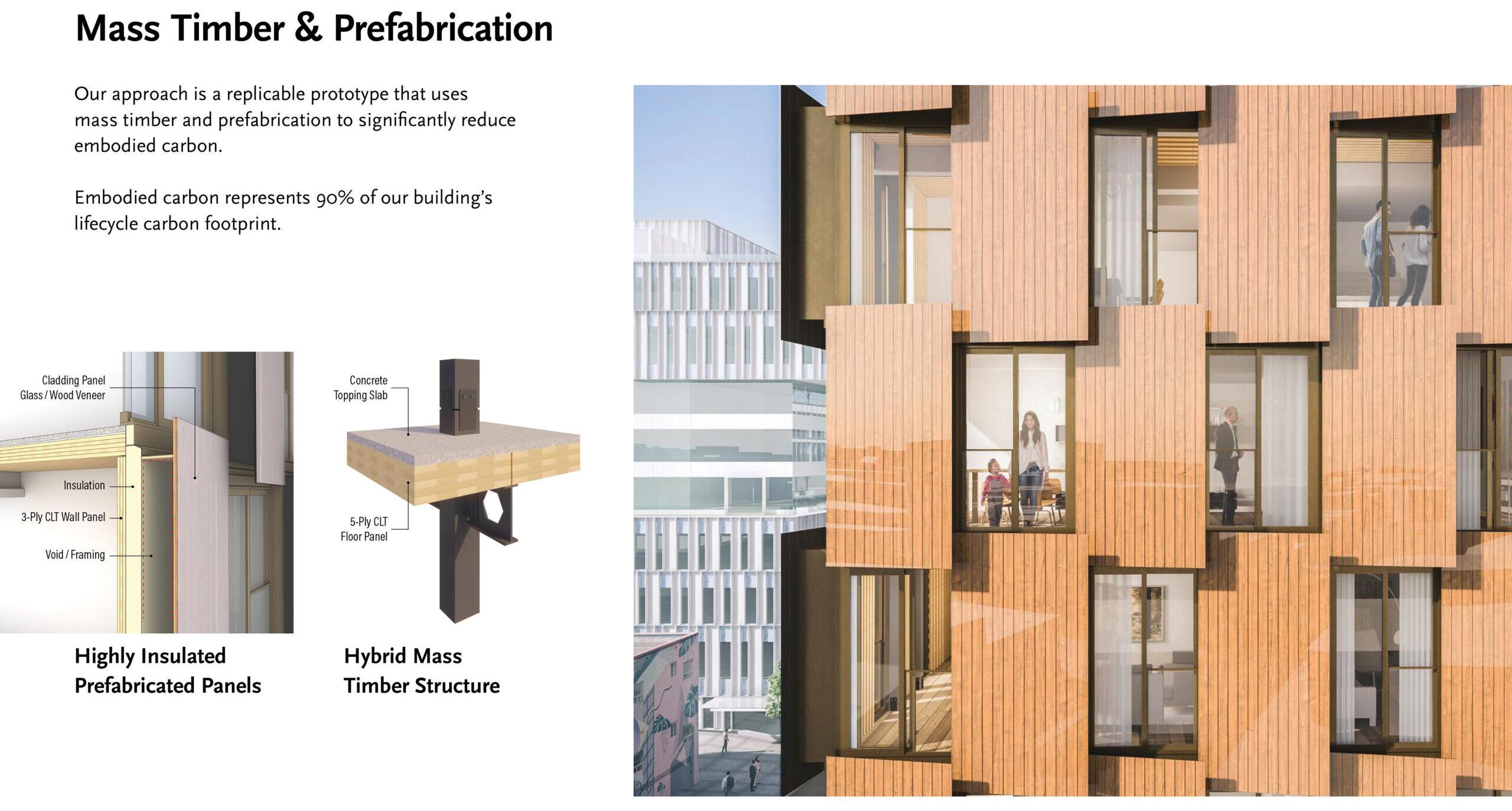

Many mid- and high-rise buildings utilize a construction system that combines timber, steel and concrete, such as the HAUT Amsterdam residential development in Amsterdam, Netherlands, the Royal Park Canvas Sapporo Odori Park building in Sapporo, Japan, and the Prototype (M5) residential tower project in Vancouver, Canada. These examples show how hybrid construction is versatile and effective in meeting the needs of modern construction projects.

Prototype (M5); conceptual design for a multi-unit housing project by Henriquez Partners Architects.

Hybrid construction and prefabrication are connected through their shared goals of enhancing efficiency, precision, and sustainability in the construction industry. By integrating materials like timber, steel and concrete, hybrid construction benefits from each material’s unique strength, while prefabrication ensures these components are manufactured — and later installed on site — with high quality and consistency in a controlled environment.

This combination reduces construction time and enhances precision, which is crucial for integrating hybrid materials. Both techniques promote sustainability by minimizing waste and improving energy efficiency. Prefabrication also supports the innovative design solutions characteristic of hybrid construction, enabling complex and flexible designs without on-site constraints. Together, they contribute to cost savings through reduced labor, optimized resource use and improved long-term building performance.

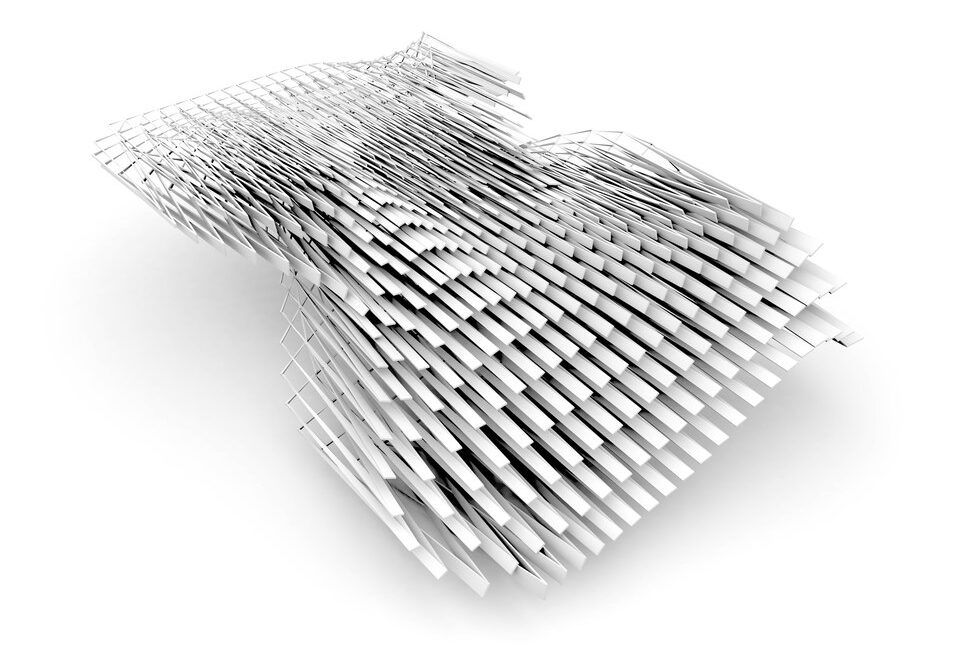

Smart Solutions: How Digital Technologies Enhance Hybrid Construction Methods

The rapid advancements in digital technologies have revolutionized hybrid construction, offering innovative solutions to the complex challenges the construction industry faces today. These cutting-edge tools enhance traditional construction practices by introducing unprecedented levels of precision, efficiency, and sustainability.

Digital Fabrication 3D model using Grasshopper. The University of Pennsylvania ARCH 744

Smart buildings with sensors and automated systems can respond to natural disasters and seasonal variations, adapting in real-time to maintain safety and comfort. On an operational level, predictive maintenance systems detect potential failures in building systems and proactively schedule maintenance, extending the lifespan of equipment. Additionally, occupancy sensors analyze usage patterns, optimizing the operation of various systems, such as lighting, HVAC and humidity levels, to ensure a healthy indoor environment.

The result? Buildings and infrastructure that are not only more resilient but also smarter. These intelligent structures adapt to changing conditions, from environmental shifts to operational demands and specific user needs, ensuring they remain efficient and effective throughout their lifecycle.

Harnessing Hybrid Construction: From Complexity to Lifecycle Benefits

Hybrid construction methods undoubtedly add complexity to projects, particularly when researching the compatibility of different materials and building techniques. This process involves extensive material testing and the creation of prototypes requiring the expertise of engineers, material scientists, and construction specialists. The projects featured above exemplify the remarkable design solutions achievable with hybrid technology. However, this innovative approach demands meticulous coordination and planning to ensure a successful outcome.

The complexities around hybrid construction make project management more intricate, where efficient communication, especially involving a broad range of collaborators like architects, engineers, manufacturers and contractors, is paramount. Synchronization between off-site construction and on-site installation is crucial, and thorough documentation and certification processes are required to ensure regulatory compliance. Installing the different components might require specialized handling, human resources, and training, which adds to a project’s complexity.

Despite the complexities involved, hybrid construction methods often bring significant benefits that outweigh the challenges. During the construction phase, hybrid techniques, which combine materials like timber, steel and concrete, enable more efficient use of resources, reducing waste and accelerating build times through prefabrication and modular methods. This approach lowers labor costs and minimizes on-site disruptions. Throughout the building’s operational phase, hybrid materials often offer superior energy efficiency and durability, leading to lower maintenance costs and a reduced environmental footprint. Hybrid buildings typically incorporate innovative design solutions that improve occupant comfort and productivity. At the end of the building’s lifecycle, the disassembly of hybrid structures is often simpler, allowing for easier recycling and repurposing of materials, thus supporting a circular economy and reducing the environmental impact compared to traditional demolition methods.

Hybrid Construction Leading the Way: Smart Solutions for a Greener Tomorrow

Architects: Want to have your project featured? Showcase your work through Architizer and sign up for our inspirational newsletters.