Architizer is thrilled to announce the world' best architecture firms in 2024, all winners of the 12th Annual A+Awards! Want to get your firm in the running next season? Stay up to date by subscribing to our A+Awards Newsletter.

The Health Sciences Education Building (HSEB) is the flagship of a new Biomedical Campus being developed in downtown Phoenix. Designed by CO Architects, this state-of-the-art facility boasts 268,000 square feet of classrooms, laboratories and clinical simulation suites, in a collaborative environment shared by the University of Arizona’s College of Medicine and Northern Arizona University’s College of Health and Human Services.

The architects, challenged with building a comfortable space for students in a city where temperatures often surpass 100 degrees, looked to the Southwestern landscape for inspiration. “The building is essentially a rock, an earth form,” explained Arnold Swanborn, the firm’s senior designer. Its massing is fissured into two cliff-like wings which rise up around a shady, open-air canyon. The inner walls of the canyon are largely glazed, saturating interiors with daylight and opening them up to natural cross breezes. While these passive design strategies were essential to creating a habitable microclimate and achieving LEED Silver Certification, it is the building’s crinkled exterior skin that makes it truly sustainable.

Photo by Bill Timmerman; via CO Architects

The design team explored a variety of options for the exterior cladding. Due to high evening temperatures, materials that stored heat for long periods of time, such as concrete and natural stone, were quickly eliminated in favor of those with lower thermal masses. After studying several light-gauge metals, including zinc and weathered steel, they settled on copper, whose durable and low-maintenance finish is ideally suited to the desert climate.

Photo by Bill Timmerman; via CO Architects

All of the copper for the project was produced from 99% post-consumer recycled content. By specifying copper early in the design process, the project team was able to procure the raw material needed for the cladding while prices were at historic lows, cutting the cost of the façade nearly in half. With 250,000 pounds of copper in hand, the architects then turned to Kovach, an Arizona-based manufacturer, to fabricate the crinkled cladding.

The cladding draws inspiration from the Sonoran Desert (left) and the saguaro cactus (right); photos via Kovach

When viewed as a whole, the cladding evokes the striated sandstone of the Sonoran Desert. This was achieved by superimposing images of nearby mountains onto digital models of the façade prior to panelization. The panels themselves are modeled after the native saguaro cactus which has evolved self-shading pleats to cope with region’s extreme heat waves. Due to their complex profiles, every panel had to be individually folded using a press brake machine, resulting in a nine-month fabrication period.

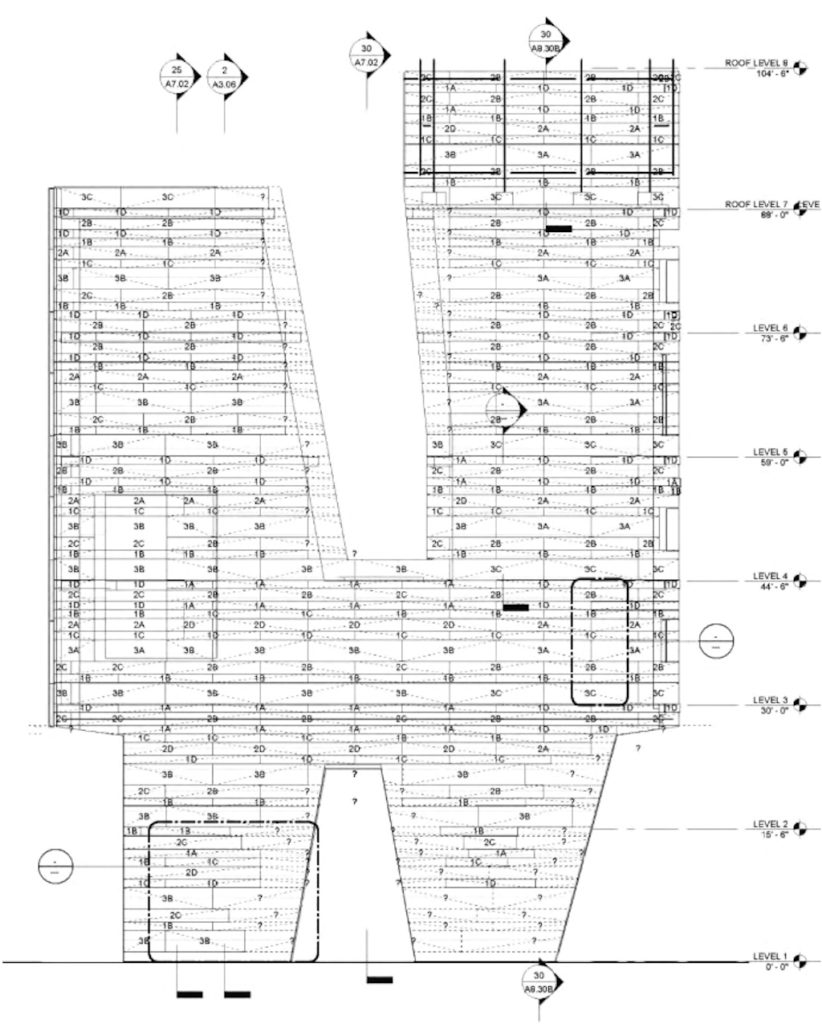

Diagram showing the panelization of the façade; via CO Architects

There are 5,972 panels in total, each 11 feet wide and in heights varying between 12 and 30 inches tall. Although there are only 26 unique profiles, they have been staggered to give the impression that no two are identical. This pattern is further obscured by 1/2-inch gaps between panels which minimize the appearance of vertical joints and allow the horizontal striations to dominate the façade.

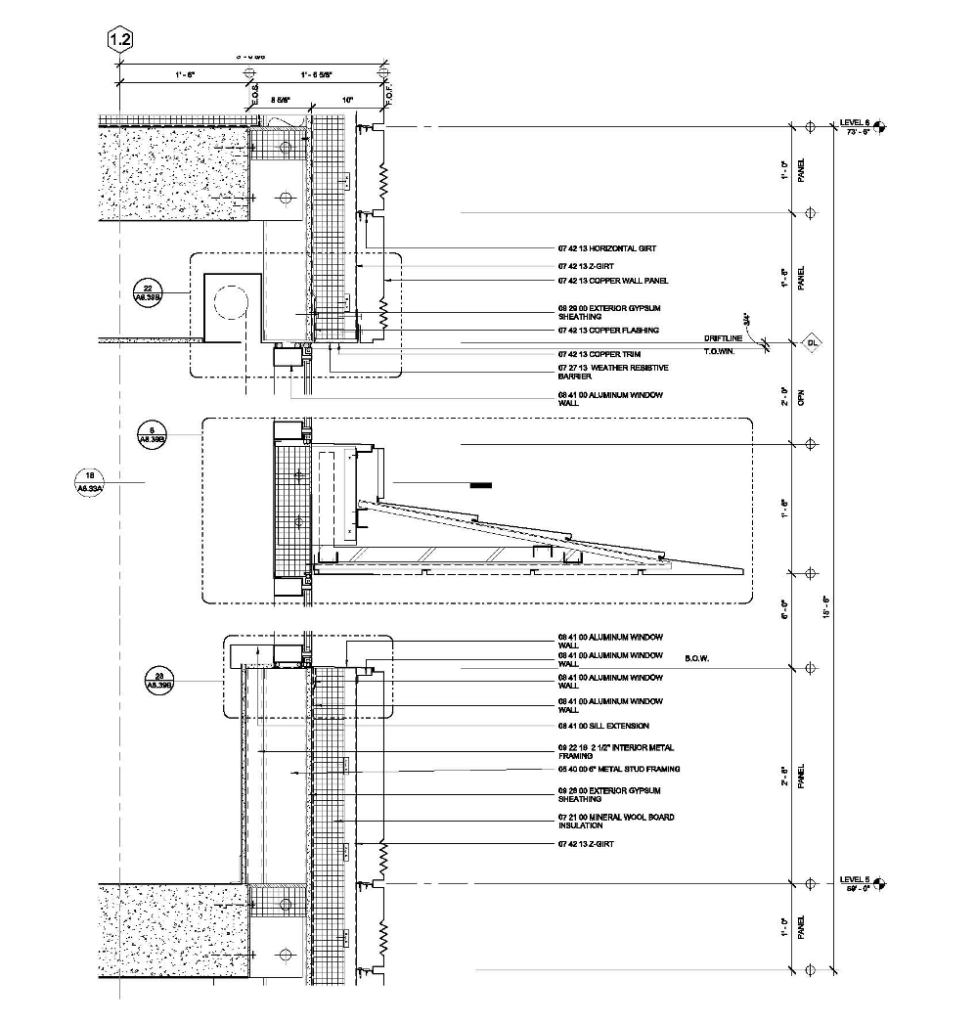

Cladding details; via The Architect’s Newspaper

The cladding is separated from the exterior insulation by a 3-inch air cavity, preventing heat from transferring to the building envelope. Instead, as the sun beats down on the copper, the heat is absorbed by the air cavity and exhausted through vents in the parapet. This creates a natural convection current which continuously draws cooler air in at the base of the façade while carrying hot air from the building.

Photo by Bill Timmerman; via Archdaily

Additional passive cooling strategies were designed in collaboration with climate engineers at Transsolar. On the southern façade, for instance, horizontal copper awnings protect ribbon windows from solar heat gain while simultaneously acting as light shelves, reflecting glare-free daylight deep into the interior. To the west, perforated copper skirts jut out at 45-degree angles, shading the extensively glazed ground floor.

Photo by Bill Timmerman; via CO Architects

Since its completion, the building has already begun to develop a gorgeous patina. Thanks to the arid climate, the copper will never lose its original, earthy color but will continue to darken with age, particularly along its creases, adding even greater depth and character to the façades.

Architizer is thrilled to announce the world' best architecture firms in 2024, all winners of the 12th Annual A+Awards! Want to get your firm in the running next season? Stay up to date by subscribing to our A+Awards Newsletter.