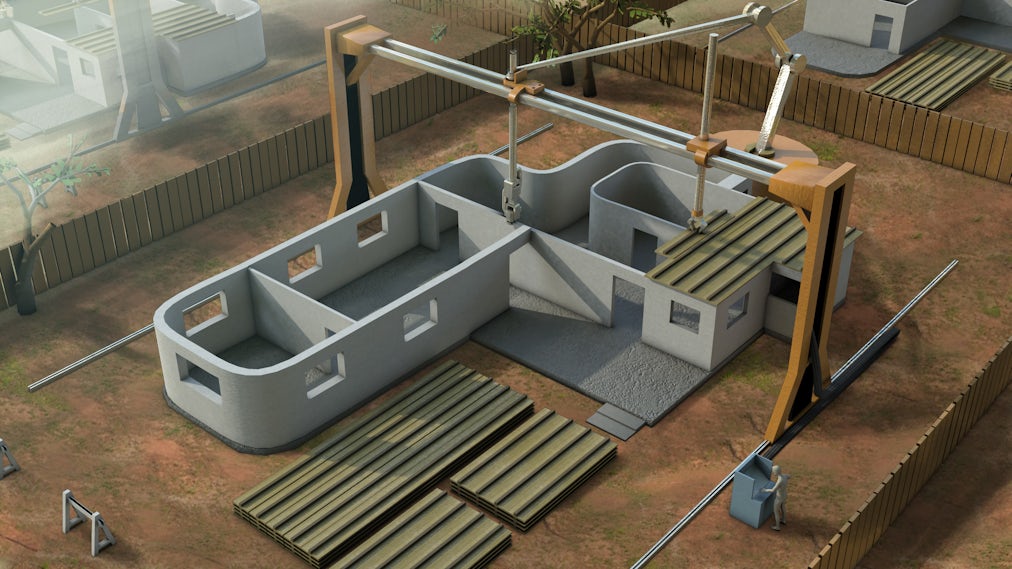

The Oak Ridge National Laboratory, the same place that developed the atomic bomb, recently produced a little white structure with a vehicle attached that it says demonstrates the future of construction. Both the structure and vehicle are 3D-printed, produced via enlarged versions of the same tabletop machines that have become popular with “makers” around the world. Building-scale printers work the same way as their smaller cousins, depositing thin layers of material over previous layers, until the form is finished.

AMIE, Oak Ridge, Tenn.; photo courtesy SOM

The idea that buildings could be printed with the click of a button has excited everyone from quirky inventors building a village in Italy to the CEO of Alphabet, one of the world’s largest companies. Designers have produced an assortment of eye-catching printed structures, taking advantage of the technique’s flexibility to create exotic forms out of plastic, concrete, metal or even salt. The pictures look nice, and 3D printing naturally has a futuristic aura out of “The Jetsons” or “Star Trek.” Evangelists claim it is the answer to the world’s housing and ecological crises, as printers will conjure cheap housing with almost no waste.

The problem is this: No one has been able to successfully take the leap from printing a fancy art pavilion to printing a functional building, and it’s still not clear if the technology is going to save the world or be another decorative footnote of architectural history.

Saltygloo by Emerging Objects, Berkeley, Calif.; photo courtesy Emerging Objects

3D printing has been around since the 1980s. Technologists developed the process, known more officially as additive manufacturing, as an alternative to other industrial manufacturing techniques, like extrusion and casting, and it has proven to be an effective, efficient way to make especially complex mechanical parts like wind turbines.

But conventional buildings are not made by extrusion or casting or any other single manufacturing process; they are accretions of dozens of different techniques from cast-and-pour concrete to spot-welded steel extrusions to laminated glass. How could one process replace the dozens of others that we currently use? Yes, that is part of 3D printing’s promise — that it’s versatile enough to do the work of multiple machines — but current printed buildings are either minimally functional, if gorgeous, pavilions or houses that are basically dumb printed boxes with traditional bric-a-brac tacked on.

The promise of printed buildings has yet to manifest, but if it does, it’s likely to come from one of these three sources:

Villa by WinSun, China; photo courtesy 3DPrint.com

WinSun

For whatever reason, the only printed buildings that look remotely habitable have been built by Chinese companies. But just because they look habitable doesn’t mean that they are. No one lives in these houses, and when you get close enough, they don’t really look like the kind of place you’d want to live, unless you have a thing for creepy-cave chic. WinSun claims to have printed 10 homes in a day and to have contracts with Saudi Arabia and Egypt to build thousands of these buildings.

There’s more than a little reason to be skeptical, though: WinSun refuses to allow observers to see their printing device, and none of the buildings seem to be occupied. It’s also not clear how much is 3D-printed; photos show printed walls but not much else. If its claims are true, WinSun’s techniques could replace cinder block–based construction common around the world, but without more transparency, it’s hard to see them as more than a publicity stunt.

Office of the Future by Gensler, Dubai, United Arab Emirates; photo courtesy of Inhabitat

Dubai

Dubai wants to become the global center of 3D printing. Why is unclear; perhaps because it’s all about the future! Or something … The United Arab Emirates has a history of grand, futuristic, failed architectural experiments (see: Masdar), but it also has a lot of money and political will to spend on developing a viable industrial niche in the post-petroleum world. So, who knows? Maybe they will print 25 percent of their buildings by 2030 like they claim. Stranger things have happened — like a sleepy desert backwater port suddenly transforming into one of the world’s most affluent nations — and Dubai has recruited Gensler and WinSun, that Chinese world leader in 3D printing.

Together they have built the world’s first printed office building, and it seems pretty nice. Maybe this thing will work. But in a nation of skyscrapers, it’s hard to see how a technology that produces modestly sized pods is going to keep up with demand. Even if the pods are somehow stacked together, they are likely to run into the same problems that traditionally built modular high-rises have run into. Again, there is a lot of hype without much to back it up other than a few model structures.

Lunar Habitation by Foster + Partners; image courtesy of Foster + Partners

NASA and ESA

NASA and the European Space Agency have some of the most ambitious plans of all: printing on the moon! And Mars! NASA is currently in the second round of an architectural competition to design a Martian colony, building on the first round where the winner proposed a dome printed out of Martian ice. The ESA is also betting on printing its lunar colony, working with Foster + Partners to design a structure that could be built out of regolith or moon rock.

The advantages here are clear: Rather than having to transport construction materials from Earth, printed buildings could use local materials as their substrate. All that would have to be transported would be the printing apparatus, which is a big saver when you consider how much of a headache it is to move stuff between planets. NASA has already started printing in space, making a little wrench with a printer on the International Space Station carried up by a SpaceX rocket, but seeing as their bigger plans are built around a literal moon shot, it’s hard to know where they will go.

Printing may open up new and unforeseen solutions, but it may also be just another manufacturing process that is incredibly efficient in some ways but not necessarily “revolutionary.” Thermoplastic extrusion may be a good analogue here: It’s incredibly helpful to make necessities of the modern age, like PVC pipe and steel I-beams, but you would never hear people getting excited about making an “extruded building.” It should sound just as silly to get excited about the idea of a printed building. Additive manufacturing is a great tool, but it alone isn’t going to change architecture.