Architects: Showcase your next project through Architizer and sign up for our inspirational newsletter.

Throughout contemporary architecture, terracotta cladding is lauded for its design flexibility, distinctive colors, natural textures, durability and sustainability. Dating back to the Babylonians, who made wide use of terracotta in palaces, temples and statues, it is a proven material that has stood for thousands of years — and will likely stand for thousands more.

Architizer spoke with Christian Lehmann — Ceramic Engineer and General Manager of NBK North America — who helped us understand the ins-and-outs of terracotta, and its modern applications as a cladding material. Founded in the late-1920s, NBK Terracotta began as a roof tile company and later branched out into architectural terracotta. As a pioneer in the industry, NBK started using terracotta as a rainscreen cladding product for exterior walls in the 1960s.

“Using terracotta as a cladding product was not very popular at that time,” Lehmann said. This began to change when Renzo Piano began working on large-scale terracotta projects in Europe, demonstrating how the material could be used in new and creative ways. Completed in 1997, one of these projects was Potsdamer Square in Berlin, which features a bespoke curved terracotta façade. “Renzo Piano’s projects were breakthrough,” explained Lehman. “The big difference was that Renzo Piano had a lot of ideas about shapes and sizes, which showcased the adaptable and geometric possibilities of architectural terracotta.”

Lawrence Public Library by Gould Evans, Terracotta by NBK Architectural Terracotta; image by Tim Griffith via ArchDaily

Categorization

According to Lehmann, there are two main approaches to cladding a building in terracotta: the rainscreen principle and precast concrete. Aside from these two approaches, in this section, we also touch on using terracotta pipes to create a sunscreen or brise-soleil effect.

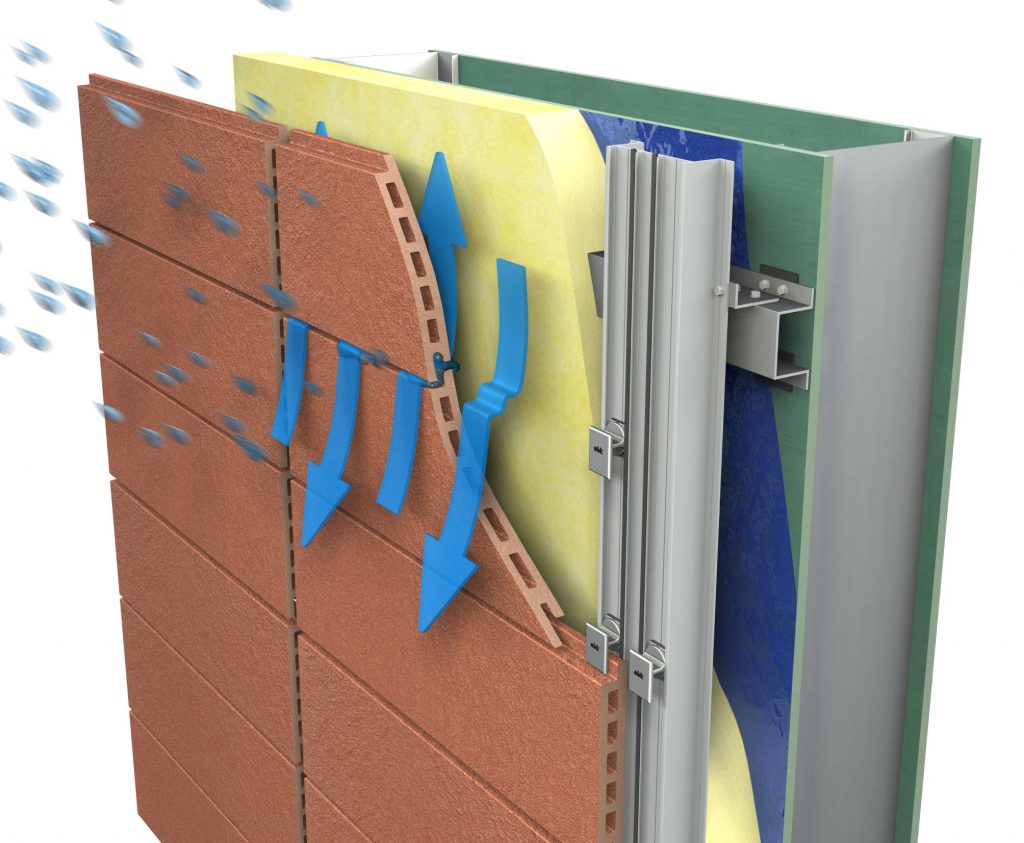

Rainscreen Principle: One of the most common ways to install terracotta is based on the rainscreen principle. Terracotta panels are hung onto an aluminum sub-support system, offering the durability of a masonry installation without the added weight. Creating a continuous insulation outboard with overlapping joints, the system is carefully designed to drain water away from the cavity that lies beneath the support structure, thus protecting the building from rain, wind and snow. Many profiles, colors, finishes and other opportunities for customization are possible.

Diagram of rainscreen cavity; image via NBK Architectural Terracotta

Another advantage of terracotta rainscreen systems is that they do not use grout or sealants such as silicone, thus avoiding the excessive number of joints associated with precast concrete panels. This greatly reduces the need for maintenance and also makes for an easier installation process that can be performed in all weather conditions.

“With a rainscreen application, terracotta is really being used to protect the building’s core, which will really prolong the lifecycle of the building,” said Lehmann.

Precast Concrete Panels: In this case, a terracotta veneer is bonded onto large precast concrete units. These systems are ideal for architects who are simultaneously looking for the strength of a precast concrete construction as well as the flexible design, profile and finish options offered by terracotta facing. “From the outside it looks like a terracotta building and from the inside, it looks like you have a solid concrete wall,” Lehmann said.

According to Lehmann, the upfront costs of precast concrete panels are typically less than rainscreen applications. However, many other costs will arise as you will have to maintain the joints between the concrete panels. Lehmann urges that if you have the budgetary flexibility, terracotta rainscreens are a shrewd investment that preclude unpredictable costs in the future.

Albion District Library by Perkins+Will; Terracotta by NBK Architectural Terracotta

Shading: As showcased in Architizer’s collection, “Fired Up: 5 Textured Buildings With Terracotta Screens,” terracotta is commonly harnessed to create lightweight brise soleils façades. Creating an open, permeable barrier, products like NBK Terracotta’s TERRART Baguette will allow you to achieve this effect. These systems are composed of ceramic pipes with square, circular or oblong cross-sections.

The Portal, Irvine by LA Architects, Terracotta by NBK Architectural Terracotta; image via LA Architects

Performance

“With terracotta you have a product that is strong, very long lasting and not harmful to the environment,” said Lehmann, “If you look at the product, which is basically a mix of clay and water, there are no chemical additives. We aren’t including any fibers to make it stronger — it’s just nature. We are doing what people have been doing for the last couple thousand years, just with more modern processes and technology. It is really a proven material.”

Life cycle: “If you compare terracotta to other cladding products, the big advantage of using terracotta is that it has a very long life cycle,” explained Lehmann. “It is possible to have a terracotta cladding product that can last 100 years without much maintenance, especially when using the rainscreen principle. In comparison, we are seeing many fiber cement façades losing colour and fading; with very high color stability, terracotta won’t change color for decades.

“I think we have a great product for US-architects to accomplish long lasting and sustainable buildings. It is not a product that is harming the environment. You can even recycle terracotta after it is used or grind it down and repurpose it in road construction, for example.”

Thermal Performance: “A terracotta rainscreen will provide a building with better energy performance than a precast system,” Lehmann said. However, if precast is detailed using a sandwich wall, you can improve that system’s energy performance.

Maintenance: According to Lehmann, “every 10 years, you may have to power wash the terracotta façade to get rid of a little bit of dust. If you have a glazed terracotta building that you haven’t maintained for 20 or even 30 years, for example, it will practically look new after power washing it once.”

Alaska State Library Archives and Museum by Hacker Architects, Terracotta by NBK Architectural Terracotta; image by Ashley Streff courtesy of NBK Architectural Terracotta

Aesthetics

The range of colors that may be achieved with terracotta are virtually endless. The material is known for its familiar red color, but its natural color variation ranges from light cream to dark grey. The addition of pigments and glazes make colors like white, yellow, blue, red, green, purple and black possible. Consult with expert manufacturers such as NBK Terracotta about the many ways that you can achieve your design goals. For starters, Terracotta can be categorized into glazed and unglazed.

Unglazed: When talking about unglazed terracotta, various colors can be achieved by mixing different types of clay. For example “you can mix red and white clay to get lighter reds or even yellowish clays,” Lehmann said. Natural fired colors typically include white, sand, yellow, taupe and a wide range of reddish hues. “To get a little bit higher variation, you can add pigments or oxides. Through firing these pigments at a temperature of about 2,000 degrees-Fahrenheit, they will react with the clay, creating stable and long-lasting colors. You will not really see a difference in color over 50 or even 100 years.”

The Center for Asian Art at the Ringling Museum of Art by Machado Silvetti Associates, Terracotta by Boston Valley Terra Cotta

Glazed: “With glazed tiles you have a body color, which is typically white or off-white, and then you have a glaze that is applied to the tiles before they go into the firing process,” Lehmann said. Beyond an endless library of color options, glazes give you the freedom to achieve different opacities and finishes. “You can have a very transparent glaze where you still see the body color underneath or a completely opaque glaze that you cannot see through at all. You also have the option of choosing between very high gloss and completely matte finishes. By combining two or three glazes on different layers of the product, other special effects, including iridescence, are also possible.”

Texture: Textured terracotta finishes are being increasingly exploited as a design feature in contemporary architecture. Textured finishes offered by NBK terracotta include fine peeled, peeled, fine combed, medium combed, sandblasted and honed. However, if there is a certain look that you are hoping to achieve, consult your manufacturer early on during the design stages of your project to see if your vision is feasible.

University of Kansas Medical Center by Helix Architecture + Design MO, Terracotta by NBK Architectural Terracotta; image by Ashley Streff

Shapes: According to Lehmann, the fact that terracotta can be used to create flexible geometric façades is still not well known among architects. “You have the chance of introducing a lot of different shapes,” he said. “It’s not only flat. You can do all sorts of three-dimensional shapes.”

“There is still a lot of unexplored potential in using terracotta as a cladding material on buildings. Only recently has the US market really started working with glazed tiles; there is definitely more to be done in that area. What I really hope to do is work with creative architects who will challenge us and the possibility of terracotta as a building product.”

Case Studies

Nembro Library by Archea Associati features terracotta by Sannini; image via Ceramic Architectures

Fired Up: 5 Textured Buildings With Terracotta Screens

Today, innovations in the manufacturing process have breathed new life into terrracotta. Now, slabs of raw clay are passed through metal dies, extruding them into long, uniform shapes, which are then fed into kilns by conveyor belts. These hollow extrusions are perfect for creating resilient rain screens and lightweight brise soleils. This collection displayed why architects still get fired up over terracotta. Check out the full story here.

Mercy Corps Global Headquarters by Hacker; Terracotta by Shildan

The Art of Terracotta: 5 Beautifully Details Examples of Ceramic Cladding

Modern terracotta envelopes and façades can be found throughout diverse building types, from skyscrapers like Renzo Piano’s New York Times Building to mixed-used developments in London. While terracotta continues to be specified for diverse commercial and educational projects, a large majority of contemporary terracotta buildings include cultural institutions and arts facilities. Taking a closer look at ceramic-clad architecture, the following collection draws together projects that are crafted with critical attention to terracotta detailing and the ways it can shape spatial experience. Check out the full story here.

Cover image features The Betchler Museum of Modern Art by Mario Botta, which is clad in terracotta Boston Valley Terra Cotta; image via Boston Valley Terra Cotta

Architects: Showcase your next project through Architizer and sign up for our inspirational newsletter.

Albion District Library

Albion District Library  The Center for Asian Art at the Ringling Museum of Art

The Center for Asian Art at the Ringling Museum of Art