Saying that British technology company Dyson Ltd. is committed to research and development could be the understatement of the century. The company spends $8.8 million every week on R&D for new products. It operates a campus in the United Kingdom where 1,500 of its engineers and scientists work on future technology. There, they ably demonstrate the company’s capabilities as a cross-category provider.

Cu-Beam Duo

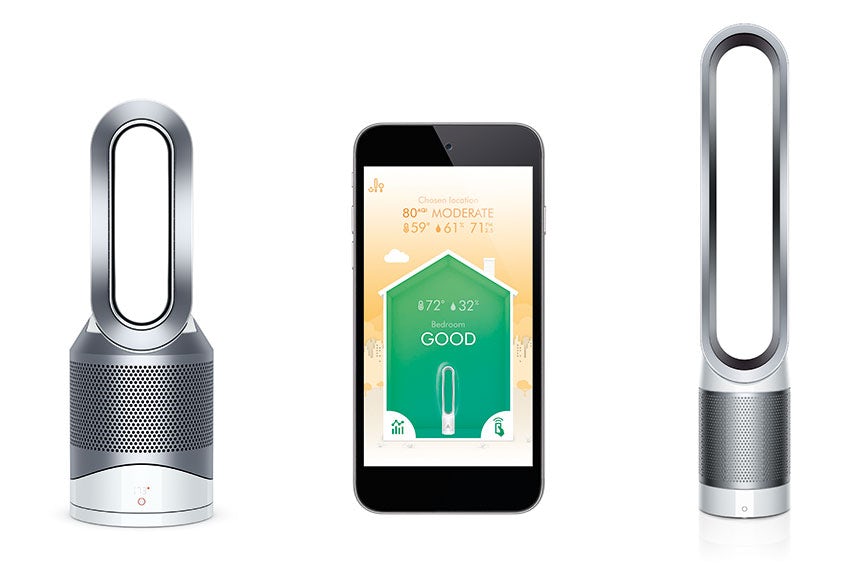

On campus, its Cu-Beam Duo suspended lights in work spaces provide flexible lighting, designed with the end user in mind. High-traffic washrooms feature the Dyson Airblade Tap hand dryer, drying hands quickly and hygienically at the sink preventing water spill on the floor. And Dyson Pure Cool Link™ air purifiers are used in meeting rooms for cleaner air.

It’s all part of a hands-on approach to R&D, according to Sam Bernard, the company’s global category director. “By solving problems and relentlessly innovating, we strive to set new standards for performance and well-being in business and leisure environments — with intelligent products and services that solve problems and delight the user,” he says.

Dyson Pure Cool Link™

When Dyson researchers seek to create a product, they start with scientific or engineering research, rather than a market-driven research perspective. The fact that Dyson is family-owned and free from shareholder pressure means it can take a long-term approach to develop its technology, without pressure to bring products to market in quick timeframes.

“We recently launched the Dyson Supersonic™ hair dryer, which is very different from other hair dryers, because we started out by studying human hair in depth — more than 1,000 miles of it, to be precise — to understand how factors like heat and airflow affect it,” he says. “Combining this knowledge with our motors expertise, we were able to rethink the hair dryer. We would never start by asking: ‘Hair dryers are big sellers, so how can we tweak an existing design to make a quick return?’”

Dyson Supersonic™

At London’s award-winning five-star Rosewood Hotel, where exceeding guests’ expectations is the order of the day, Dyson products are de rigueur. “Dyson Supersonic™ hair dryers, Dyson Pure Cool Link™ air purifiers and CSYS™ task lights are provided in the rooms, offering guests the latest in hair drying, air purification and task lighting technology,” he says. “And Dyson Airblade™ hand dryers are used in public restrooms, while housekeeping staff use Dyson V8 cord-free vacuums.”

Jake Dyson, the company’s lighting product designer, says each of these innovative products is the result of the firm’s underpinning design philosophy: Use a science- and research-led approach to create products that solve problems and hopefully improve people’s lives in a simple and intuitive way.

Jake Dyson

Jake’s particular expertise in LED lighting design runs strong and deep. He studied industrial design at Central St. Martins in London, then worked as a designer in the retail sector after graduation. “While working on a project, a request was made for a very distinct type of light fixture, which no one was producing. So, I set out to create the product myself,” he says. “That sparked my passion for LED lighting.”

CSYS™

He could see that LEDs held vast potential for domestic and commercial lighting, but wasn’t keen on how many other companies were using them. “They were either being placed inside disposable light bulbs — which are part of the throwaway culture that I really dislike — where they tended to produce a weak, blue-ish light that compared unfavorably to existing types of bulb,” he says. “Or LEDs were being mounted within light fittings but without adequate cooling in place.” If the temperature of LEDs isn’t managed, their coatings can become damaged thermally, which causes a loss of brightness and fluctuations in color relatively soon. “That means the quality of the light was suffering, or you were seeing entire fixtures that would have to be replaced after just a few years,” he says.

Cu-Beam™

The other consequence of not cooling LEDs is that they’re restricted to using low-power units as a trade-off to ensure longevity. “This leads to unfocused light with many lower-power LEDs having to be placed behind diffuser panels, losing the ability to direct the light precisely,” he says. “I knew there had to be a better way.”

And he set out to find it. In 2004, he created his own company to invent, manufacture and sell LED lighting. By 2015, he’d brought his company into the Dyson fold established by his father and added lighting as a new category offering within the commercial product portfolio. Among the lighting products offered are the Cu-Beam™ suspended lights and CSYS™ task lights.

They join an innovative and highly successful product line for hand dryers that include the Dyson Airblade V, the Dyson Airblade dB and the Dyson Airblade Tap, as well as air treatment products like purifiers, heaters, humidifiers, fans and allergy-relieving technology.

Dyson Airblade V

Each Dyson product is designed for its one-of-a-kind function. “I’m an engineer at heart, as I’m fundamentally interested in the way things function, and how they can be improved to work better and solve problems,” Jake Dyson says. “When I create a product, I always start from a functional perspective rather than setting out to create a particular aesthetic.” He finds inspiration in the midcentury modern designs of Charles and Ray Eames, well known for their form-fitting and sculptural lounge chairs. The couple wanted the functionality of a piece of furniture to dictate the look of the piece, and designed it with the intent that it would last a lifetime. “Their designs were created back in the mid-20th century and are still bestsellers, thanks to their timeless form grounded in functionality, rather than styling,” he says. “As designers, they turned the concept of furniture design on its head, demonstrating that good design lasts, whereas fashion inevitably goes out of style.”

They were also meticulous as they researched function and developed appropriate materials — qualities that the engineers, scientists and designers at Dyson also share. The result for them, too, will likely result in functional, sculptural designs that last well into the future.