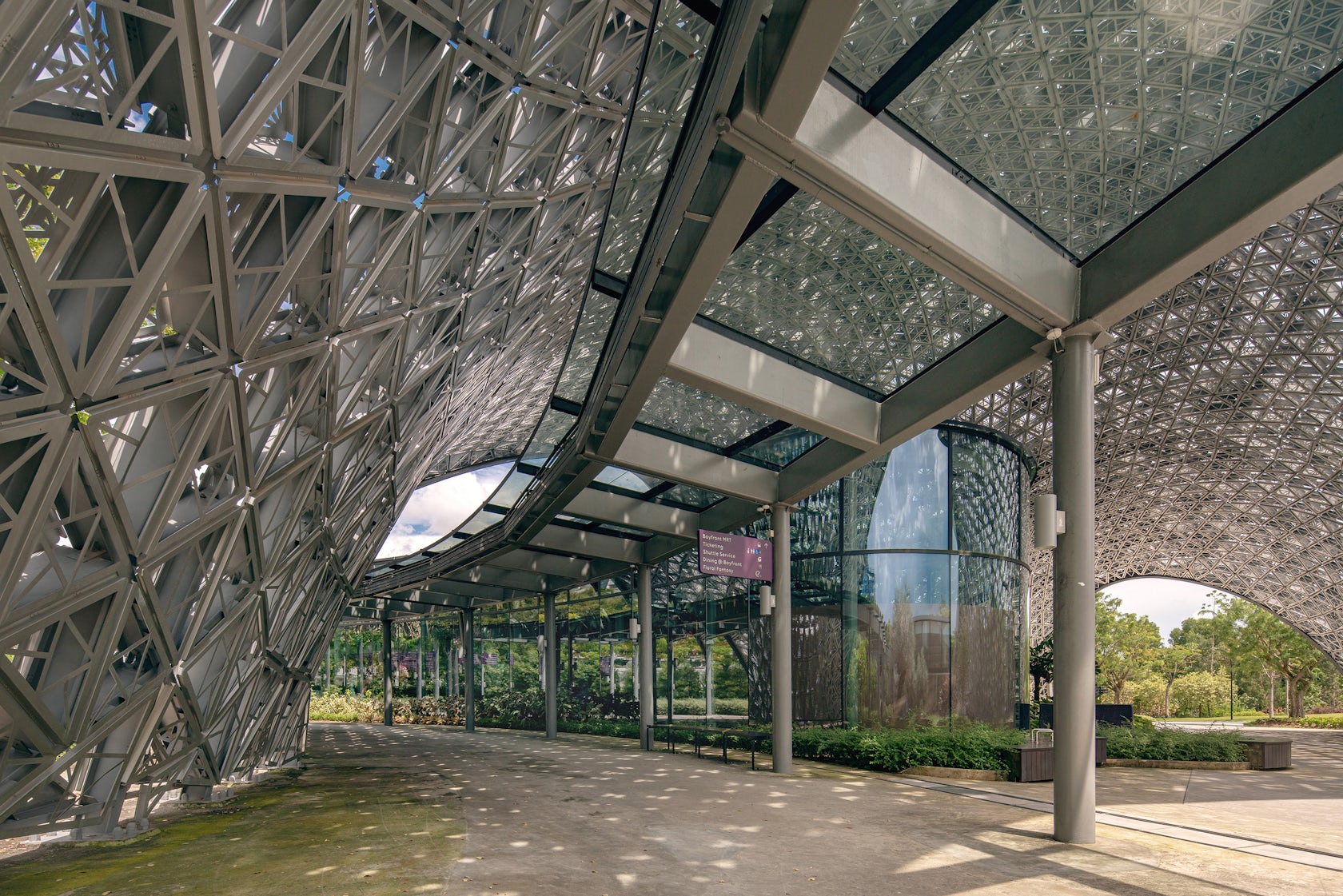

The Future of Us Pavilion – Located in Singapore’s Gardens by the Bay, the Bayfront Pavilion, also known as The Future of Us Pavilion, follows the grand tradition of experimental architectural structures that evoke a dialogue with nature by blending an intricate form with a perforated skin fluidly with the adjacent environments. For visitors, it offers a climatically comfortable outdoor environment and a stunning visual experience akin to walking under the foliage of lush tropical trees. There is a clear mathematical logic to the design that was determined by extensive environmental simulations and structural optimisations. Material usage was optimised, and the embodied carbon footprint minimised, pointing the way forward for the building industry to adopt similar ‘green’ design tools and methods in the future.

Architizer chatted with Prof. Dr. Thomas Schroepfer, Director at SUTD Advanced Architecture Laboratory, to learn more about this project.

Architizer: What inspired the initial concept for your design?

Prof. Dr. Thomas Schroepfer: The inspiration for the Pavilion was the environmentally comfortable and visually beautiful experience of walking under the foliage of lush trees in the tropics. This idea was translated into a design with a clear mathematical logic that was determined by extensive environmental simulations and structural optimisations. The analyses and their application to a detailed computational model led to an optimum solution for the structural form and pattern of the Pavilion. Material usage was optimised, and the embodied carbon footprint minimised, pointing the way forward for the building industry to adopt similar design tools and methods.

© SUTD Advanced Architecture Laboratory

This project won in the 10th Annual A+Awards! What do you believe are the standout components that made your project win?

According to Tan Wee Kiat, former CEO of Gardens by the Bay, the success factors of the Pavilion are obvious. The hot and humid climate often dissuades people from visiting the Gardens. To enhance visitor comfort, its landforms were designed with wind direction in mind, while foliage and shelter provide as much shade as possible. The Pavilion is based on similar ideas. These are beautifully translated into a contemporary aesthetic and functional form that is determined by thorough environmental analyses. An enthralling vision for a garden of the future is thus encapsulated.

© SUTD Advanced Architecture Laboratory

What was the greatest design challenge you faced during the project, and how did you navigate it?

Due to the very short implementation timeline for the project (six months), a high level of integration between digital and construction technologies as well as building processes was needed to make the rapid production of a large number of individual elements that make up the complex freeform structure of the Pavilion possible. Its primary structure is made from steel. The inner and outer skin of the shell consist of triangular aluminium panels of varying size and perforation fabricated with laser cutting machines. The use of advanced design and fabrication methods throughout the project allowed for the prefabrication of most of its parts and the efficient, cost-effective and accurate construction of its geometrically complex form.

© SUTD Advanced Architecture Laboratory

How did the context of your project — environmental, social or cultural — influence your design?

Originally built to house The Future of Us, the fiftieth anniversary capstone event of Singapore, and completed for its current purpose in 2019, the project has become a permanent landmark in Gardens by the Bay that continues to serve as a public space and venue for community and cultural events.

© SUTD Advanced Architecture Laboratory

What drove the selection of materials used in the project?

The analysis and its application to a detailed computational model led to an optimum solution for the structural form, material choices, and pattern of the project. The latter was produced with an algorithm based on triangulation, which allowed each aluminium panel to be filled as required by the assigned environmental performance up to a level that is almost solid. The use of advanced design and fabrication methods throughout the project allowed for the prefabrication of most of its parts and the efficient, economical and accurate construction of its geometrically complex form.

© SUTD Advanced Architecture Laboratory

What is your favorite detail in the project and why?

My favourite project detail is the connection of the inside and the outside approximately 11,000 aluminium panels that are all different to the steel ribs. This allows for a shell that has a thickness of only 20 centimetres, spans about 50 metres and covers an area of about 2,000 square metres. The shell allows is a visual experience akin to walking under the foliage of lush tropical trees.

© SUTD Advanced Architecture Laboratory

How important was sustainability as a design criteria as you worked on this project?

There is a clear mathematical logic to the design of the Pavilion that was determined by extensive environmental simulations and structural optimisations. The analyses and their application to a detailed computational model led to an optimum solution for its environmental performance (perceived temperatures in the Pavilion can be up to 20 degrees Celsius lower than in its surroundings; this is achieved through highly calibrated passive design measures only) as well as structural form and pattern. Material usage was optimised, and the embodied carbon footprint minimised, pointing the way forward for the building industry to adopt similar ‘green’ design tools and methods in the future.

© SUTD Advanced Architecture Laboratory

In what ways did you collaborate with others, and were there any team members or skills that were essential in bringing this Award winning project to life?

Our team produced drawings for the steel structure, the cladding, the cut sheets and the installation of the panels. The required close collaboration with other members of the construction team was achieved by using a shared lightweight and platform-independent computational master model in that every structural element of the project was represented by a centreline. The master model was also used to evaluate the triangulation of the overall structure in terms of its structural, environmental, and aesthetic performances.

© SUTD Advanced Architecture Laboratory

How have your clients responded to the finished project?

Over the course of the 100-days-long Future of Us exhibition, the Pavilion had about 400,000 visitors. Many of them expressed that the Pavilion should be kept after the end of the event. The Singapore Government subsequently decided to make it a permanent structure.

Team Members

Thomas Schroepfer (Lead), Alex Cornelius, Aloysius Lian, Thomas Wortmann, Amanda Yeo Qian Yu, Joel Yap Kar Ying, Yehezkiel Wiliardy Manik, Christyasto Priyonggo Pambudi

Consultants

Pico Art International, S.H. Ng Consultants, Passage Projects, Protag Tetra, Engineering Management Solutions Platform, Applied Research Consultants

For more on The Future of Us Pavilion, please visit the in-depth project page on Architizer.

The Future of Us Pavilion

The Future of Us Pavilion