The votes are in, and Architizer is thrilled to unveil the winners of the A+Product Awards! Register for Architizer's A+Product Awards Newsletter to receive future program updates.

Hello, old friend. No, dear reader, I’m not talking to you; I’m talking to that wood flooring over there. We’ve been close for ages.

But who isn’t friends with wood floors? They’re the best! People have been covering their floors with wood planks for centuries, and no one seems to be changing their mind anytime soon. Some things never go out of style.

Technically, wood isn’t the most complicated building material, but it does come with a lot of choices. The main concern is aesthetics: the species, color, grain and finish of the wood and how it’s cut and installed into your space. Sometimes, the room will require a softer or harder wood depending on how the floor is being used, but there are so many durable finishes nowadays that wood suppliers should be able to work with you to achieve your vision. Use normal words and photographs to describe what you are after and be sure to describe how the space is going to be used. Also give the dimensions of your space. The manufacturers will do the rest.

Mind the gaps in old butt-jointed boards; image via Imgur (Fuzzledorf).

The rest of the articles this week will get into what’s new and hot in wood flooring, so we should cover the basics here. First: If you don’t know how wood flooring is installed, you should. It involves something called ‘tongue and groove.’ Tongue and groove is not, though it may sound like it, something that might happen on a particularly risqué dance floor. It is the relatively ingenious way that floorboards fit together. Early boards were simple rectangular planks that were butt-jointed against each other, but as wood dries and ages, the gaps between the boards can grow, filling your floor with unsightly dust-collecting canyons.

Diagram via DIY Network

Wood boards are individually installed going down in lines across the room. Boards are typically nailed to a subflooring, which is often a sheet of plywood or particleboard. The nails go into the tongue of the board, which is covered beneath the neighboring piece, so the nails are invisible in the finished installation. Extra layers of membranes or engineering can be added under the boards to reduce sound. Typically, the ends of floorboards butt against the wall finish. The result may be an irregular edge that is usually covered with a piece of trim.

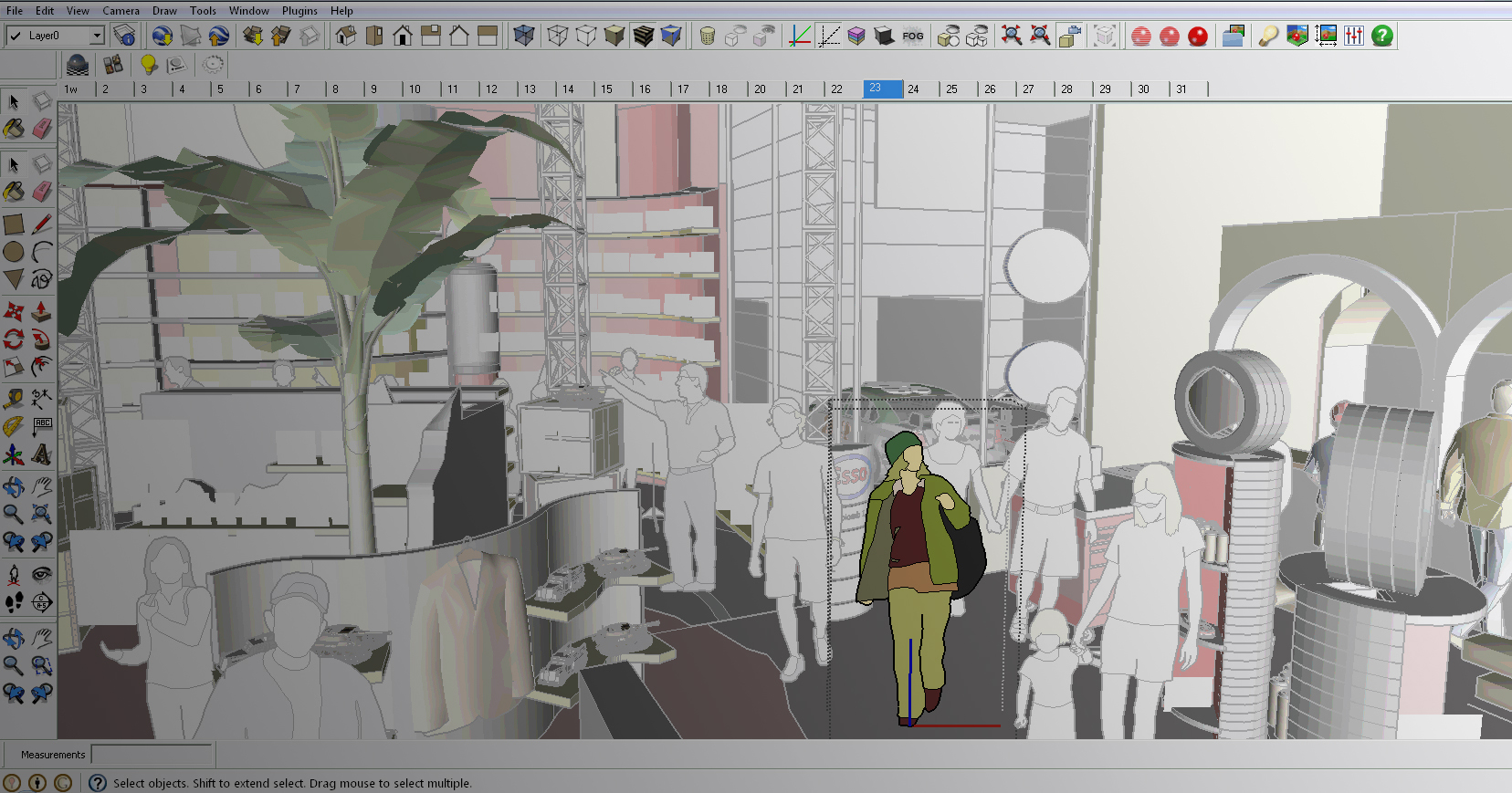

New wood flooring pattern from Listone Giordano used by Zaha Hadid Architects in the City Life Residence; image via Bluebell Products

New styles stray from the typical board model, offering wood panels in modern and parquet-inspired patterns. Engineered wood floors are also standard now. Many are visually indistinguishable from solid hardwood, and they are usually stronger and more durable. Wood imitators made out of linoleum or ceramic tile are getting more and more sophisticated. Some closely match the look of real wood, and they’re usually cheaper. Don’t be afraid to explore all of your options.

There are a variety of major international flooring manufacturers, but there are also local suppliers that can provide more custom options. Check out what’s on Source and see what fits your needs.

Got it? Great! Now we’re all friends. Let’s get down to the details:

Common Dimensions

Wooden floors come in strips, planks and tiles.

- Strip: Often considered a “traditional” wood floor. Strips range in thickness from 5/16 inches to 3/4 inches and are available in widths that range from 1 inch to 3 inches.

- Plank: Wider than strip wood, planks are available in 1/2-inch and 3/4-inch thicknesses and multiple widths ranging from 3 inches to 12 inches, in 1-inch increments.

- Wide Plank: Typically, plants wider than 5 inches are considered to be unusually wide and may not be as easily available.

- Tile: Length varies but is normally short. Thickness can vary from 5/16 inches to 3/4 inches.

Aesthetic

- Area: Describe the dimensions of the building and floor plan to determine the total area of wooden flooring required.

- Species: Wood varies greatly in aesthetic depending on the species of tree from which it is derived. The most common variants include oak, maple, hickory, birch and cherry, while more exotic woods include teak, acacia and tigerwood. Each has different colors and grain patterns. For a complete list, you can visit the Wood Database.

- Grade: Many associations, manufacturers and suppliers that serve the vast market of solid wood flooring have proprietary grading standards. The National Wood Flooring Association (NWFA) lists:

- Clear wood – minimal character marks that provide a uniform appearance

- Select wood – natural heartwood/sapwood color variations, knots, streaks, etc.

- Common wood – more pronounced natural characteristics than select wood

- Color: Wood naturally varies in color from light yellow to dark brown, but it can be stained and dyed any color.

- Grain: Different varieties and cuts of wood will have different patterns in their grains. Some will have many knots, others elaborate veins and others will have elegant striation.

- Cut: There are a variety of cuts available for wood floors. The name refers to how the plane was cut from the wood log. Certain cuts waste more wood from the log and are more expensive. Because of how the grain manifests in the plank, each cut results in boards of different strength and appearance.

- Plain-sawn is the most common cut because it is cheapest, but it is less stable than other options. It’s the most efficient way of cutting a log.

- Quarter-sawn wood is cut against the grain, which wastes more wood but results in a board that warps and distorts less with time. It is more expensive than plain-sawn.

- Rift-sawn is the most expensive wood. It can be cut as a complement to quarter-sawn wood (see diagram below), or it can be made by radially cutting the log. This produces a very stable board with a very even linear cut.

- Live-sawn wood is made by just slicing across the log. It makes the widest boards, but boards made from the same log may widely vary. The edges can also be left unfinished (or ‘live’), although you’d have to get creative about how to fit them together.

Diagrams via Palo Duro Hardwoods

Performance

- Durability: The most important characteristic of a solid wood floor is its durability: the capacity to resist wear, denting and marring. This is defined by the Janka Hardness Rating (ASTM D-143). Hardwoods are more durable than softwoods and are therefore more often used for wood flooring than are softwoods. A room’s function will often dictate the optimal hardness Janka Rating. Information on the characteristics, grades, strengths and mechanical properties of American hardwoods can be found by referencing the Hardwood Council’s Species Guide.

- Finishes:

- Surface Finishes – Durable and water-resistant blends of synthetic resins most often referred to as urethanes or polyurethanes. They remain on the surface of the wood to form a protective coating.

- Water-based finishes appear clear and resist yellowing over time.

- Oil-based finishes appear amber in color.

- Acid-cured finishes appear clear to slightly amber.

- Moisture-cured finishes appear clear to amber; extremely durable and more moisture-resistant than other surface finishes.

- Wax finishes – Soak into the pores of the wood and harden to form a protective penetrating seal, which will appear low luster and amber in color. They have a mild odor when applied and will dry in a variable amount of time depending on the type of wax used and the job-site conditions. Wax finishes are durable but will show spots from water and other contaminates.

- Acrylic impregnated finishes – Injected into the wood to create a super-hard extremely durable floor. Acrylic impregnated finishes are most often used in very high-traffic areas.

- Ultraviolet-cured finishes – Waterborne finishes that are cured by ultraviolet light. Multiple sheen levels are available to suit your taste.

- Penetrating and hardening oils – Tun oils, linseed oils or other natural oils that assist in drying and hardness.

- Surface Finishes – Durable and water-resistant blends of synthetic resins most often referred to as urethanes or polyurethanes. They remain on the surface of the wood to form a protective coating.

- Engineered or Solid: Solid hardwood floors are made from single pieces of wood cut from a log (see cuts above). These floors can be sanded and refinished as many times as you could want, but they will warp and age over time. Engineered wood is much more stable. It is a sandwich of wood veneers over a core of medium-density fibreboard (MDF) or a similar material that will not distort over time. Because the veneer on engineered wood is relatively thin, it can’t be sanded and refinished to the same extent as solid wood.

Visit Architizer’s Product Catalog to check out the latest wooden floors products.

Categorization

Architizer: Finishes >> Floors >> Wood Flooring

Masterspec: 096400

MasterFormat: 096400

Does your company manufacture wooden floors? Click here to learn more about listing your product on Architizer. If you have comments, questions or suggestions, let us know in the comments section below.

External Links

Guide to American Hardwood Species

The Wood Database

National Wood Flooring Association

The votes are in, and Architizer is thrilled to unveil the winners of the A+Product Awards! Register for Architizer's A+Product Awards Newsletter to receive future program updates.