Architizer's new image-heavy daily newsletter, The Plug, is easy on the eyes, giving readers a quick jolt of inspiration to supercharge their days. Plug in to the latest design discussions by subscribing.

Let’s talk timber. More specifically, let’s talk solid vs. engineered wood flooring. There’s a sheer difference between the two types, and it’s key that architects get the dirt on which one’s which and why the right kind — and its respective thickness — might best benefit a project.

But before we dig deep into the material and how it’s processed into pristine architectural flooring, there’s something you need to know: Wood moves. Timber is constantly in a state of expansion and contraction due to the levels of moisture it’s surrounded by, and that’s a problem if you’re trying to slap down a stable product that’s sturdy enough to walk on and hold hundreds of pounds of furniture. Modern wood flooring manufacturers must craft planks that minimize or restrict this natural movement. The easiest way to do this is through engineered wood.

White Oak engineered wood wide-plank flooring; image via Carlisle

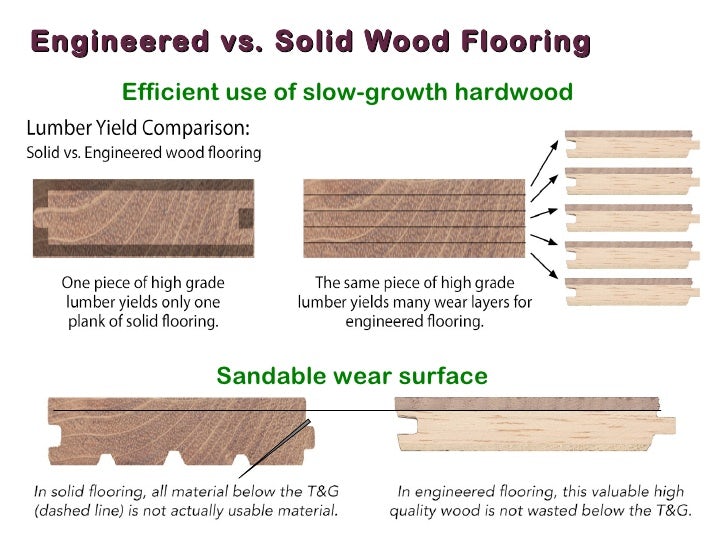

That’s fake wood, right? No, engineered wood flooring isn’t fake wood per se. In fact, it’s 100 percent made of wood, but it’s not homogenous. It consists of thinly sliced layers of hardwood over top of a cross-plywood base. Engineered wood is significantly cheaper than solid hardwood and can be quickly adhered to another wooden surface, a concrete floor or a soundproofing mat. Plus, it’s easy to install over radiant heat — hence less expansion and contraction.

But engineered wood is simply a veneer for your floor. By definition, it is slender and therefore can be difficult to sand or refinish after years of wear and tear because it’s so thin. Even the best of its kind can only handle up to three finishes.

Image via flooriations.me

Certain manufacturers, like New Hampshire–based Carlisle Wide Plank Floors, suggest a maximum veneer of 3/16 of an inch thick with a 9-ply or 11-ply core — resulting in a 5/8- to 3/4-inch-thick plank. That’s way above normal. The average industry standard for the wear layer (or veneer) on engineered wood flooring ranges from 1/12 to 1/8 inch thick, but it truly depends on the cut coming from the company you’re working with.

Carlisle notes there are two methods of cutting the veneer layer: dry-sawn face done with a saw blade; or a sliced and rotary-peeled face done with a knife blade. The former gives you a thicker veneer layer — one that’s similar to solid hardwood flooring, while the latter produces a thinner veneer layer usually around 1/13 inch. In this case, the result ends up looking more like plywood and is susceptible to future water damage thanks to the boiling process before the wood gets peeled.

Image via Carlisle

Another important factor to consider is width. Typical flooring of this kind is usually 3 inches wide and 3 feet long, but the wider and longer the plank, the less seams will be seen. Six- to 10-inch-wide boards with lengths ranging from 2- to 12-feet-long can reduce the appearance of seams by up to 500 percent, according to Carlisle.

Solid Hardwood Flooring; image via Carlisle

Pure, solid hardwood flooring, which comes from a single species, can be specified at the same overall thickness, width and length as engineering wood flooring but is generally considered stronger because each plank is one continuous natural piece of wood. Armstrong Flooringrecommends installing planks that are 3/4 inches thick — the industry standard — so that any future finishing efforts won’t diminish the floor’s overall strength.

It’s safe to assume each round of sanding will take away approximately 1/8 inch off the surface of the floor, but keep in mind that sanding has a stopping point. The tongue-and-groove portion of the plank must never be interfered with. Solid hardwood is normally nailed or stapled to a wooden subfloor at or above grade, and, depending on thickness, it can significantly decrease the floor-to-ceiling height of a space. It is also much more susceptible to shrinking and expanding, as mentioned before. Every precaution must be taken to ensure its stability.

Image via dogmainrecords

Choosing the right wood flooring for a project is not a simple task. Each project might require a little finessing based on its location, size and the depth of performance needed. But to make the most basic decision on wood flooring, you must be aware of these things and seek out manufacturers that will produce the right product for you. It’s all about the difference between thick and thin wood. Once that’s clear, it’s time to move on to finishings and coatings and, if you’ve completely given up on natural wood, look at laminates.

Architizer's new image-heavy daily newsletter, The Plug, is easy on the eyes, giving readers a quick jolt of inspiration to supercharge their days. Plug in to the latest design discussions by subscribing.

Header image via WB Designs