Find the right building-products for your next project through Architizer’s new community marketplace for building-products. Click here for more information. It’s free for architects. Are you a building-product manufacturer looking to connect with architects? Click here.

Architect Jeff Jordan hasn’t forgotten what matters most when designing great buildings.

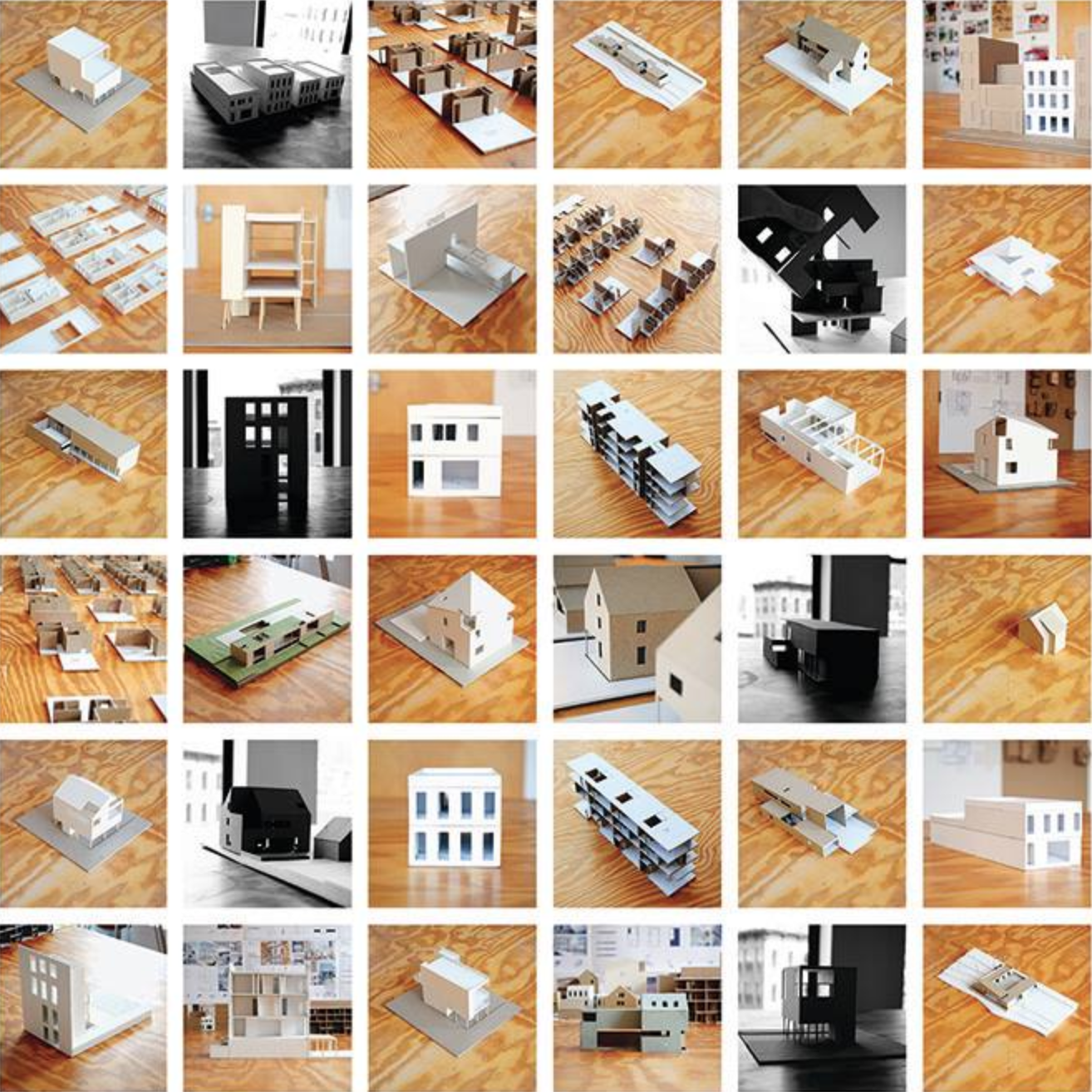

With digital fabrication now dominating the profession, it is notable that Jordan’s studio is populated with a huge array of handcrafted models. Each tactile object is a unique representation of a project the architect’s Jersey City-based practice has worked on, and each speaks to his firm’s wider philosophy when it comes to construction. These models reflect a belief that a strong understanding of the making process and attention to detail is key to making architectural concepts a reality.

Image via Jeff Jordan Architects

Like his models, Jordan’s full-scale buildings require a careful process of material selection to ensure that each element complements and elevates the next. The trouble is, Jordan explained, that process can be an arduous one.

“While finding the right products and manufacturers are an important part of the process,” said Jordan, “it’s easy to find yourself going down a rabbit hole of online research for an email address for just one local dealer, which is time that we’re not able to work on other aspects of our projects.”

For this reason, Jeff Jordan Architects is now using Architizer’s marketplace to find and specify building-products in a more efficient way. Jordan’s team of architects is already starting to feel the time-saving benefits the platform brings, giving them back more hours to focus on what they do best — creating beautifully detailed architecture using the best products available.

Higgins Lake House by Jeff Jordan Architects, Higgins Lake, Mich.

Architizer spoke with Jordan about his firm’s origins, his approach to specification and the incredible impact of using elemental materials in innovative ways.

Paul Keskeys: Tell us a little about your firm — how did all begin?

Jeff Jordan: We are a small, design-oriented office with a focus on single- and multi-family residential design. Ironically, the office started during the 2008-2009 Recession. At the time, I was working full time in a great office, had a couple of small side projects and was about to start a part time studio teaching gig at a local university. I also had two young sons with a third on the way.

I was approached to design a new single-family house and decided that the combination of my side work, the teaching gig and the new house (as well as the growing family) made going out on my own a reasonable, if risky, endeavor. I also knew that architects were being laid off throughout the industry and my own position could be at risk.

So, I set up a workspace in my basement, had a couple of slow years until some of the work I was doing was completed, had the work photographed and was lucky enough to get published. I went from working alone to having a team of four within a year. We have been busy ever since.

Detail from Sea Bright House by Jeff Jordan Architects, Sea Bright, NJ

Which of your current projects are you most excited about and why?

There are several exciting projects underway. We are wrapping up construction on a fantastic renovation/addition of a very unusual mid-century modern house in Jersey City. Additionally, we are about to start construction on a big multi-family project in Jersey City, a new single family rowhouse in Hoboken, a renovation and addition to a vast residential compound in Princeton, and even a new coffee shop space in Millburn.

What do you feel is most important to consider when it comes to choosing materials for buildings?

Most of our projects come with tight budgets and clients who are interested in a combination of materials that look good and require no maintenance. That means we are often trying to find a balance between quality and cost when choosing materials. The two aren’t mutually exclusive, but having a limited amount of money to work with means a lot of the options we are initially drawn to aren’t viable.

Which methods do you usually use to source materials for your projects?

We use a combination of previous experience, contractor and client recommendations and ongoing research to source materials. Once we find something we like and can trust, we tend to re-use it on multiple projects.

Montclair House by Jeff Jordan Architects, Montclair, NJ

What is the biggest challenge for you when it comes to the specification process?

Getting the specified product to actually be used in the project. It’s great to receive recommendations or requests to use an alternative equivalent product that is, for example, easier to install or less expensive. However, sometimes it’s simply a lack of familiarity that causes a product to be replaced by that of a different manufacturer. While we don’t object to a solid reputation or “tried and true” approach, it can potentially be limiting.

What advantages do you find in using Architizer to source materials and products?

It’s like having extra staff helping with materials and product research. As a small firm, each staff member carries multiple projects, mostly on their own. While finding the right products and manufacturers are an important part of the process, it’s easy to find yourself going down a rabbit hole of online research for an email address for just one local dealer, which is time that we’re not able to work on other aspects of our projects.

Architizer allows us to put our inquiry out to multiple potential manufacturers in one go, and returns with a range of relevant products and real people representing those products who are able to provide detailed information. It has connected us with people and products we might not have encountered otherwise.

What do you think building-product manufacturers should care about most when developing their products?

A balance between cost, performance and aesthetics. Buildings are expensive and generally should last for decades or more. The materials that make them up need to be obtainable, durable and beautiful.

Therme Vals by Peter Zumthor, Vals, Switzerland

What is your favorite application of a material in a project by one of your peers?

The extensive and rigorous deployment of quartz slabs in Peter Zumthor‘s Therme Vals project is a longtime favorite. Walls, floors and ceilings constructed of the same beautiful material are sublime. By the way, a peer is someone who is more or less an equal. Peter Zumthor is obviously on a much different level.

What advice would you give to young architects when sourcing materials for a project for the first time?

Find a balance between materials that reinforce your vision and ones that are reliable. That may mean working with materials that have a long history of use and perhaps feel a bit dated, but there may be a way to deploy them differently. Oh, and have fun!

Search for the perfect architectural materials through Architizer’s new community marketplace for building-products. Click here to sign up now. Are you a building-product manufacturer looking to connect with architects? Click here.

Higgins Lake House

Higgins Lake House  Montclair House

Montclair House  Sea Bright House

Sea Bright House