Architects: Showcase your next project through Architizer and sign up for our inspirational newsletter.

Terracotta, which means ‘baked earth’ in Italian, is a traditional ceramic created by firing clay in special furnaces, called kilns, at high temperatures. The malleability of the unfired clay allows it to be hand-molded into intricate shapes, which harden significantly when heated. Although terracotta was initially invented for pottery and sculpture, craftsmen soon realized its potential as a building product and began producing terracotta bricks, cladding and roof tiles.

Today, innovations in the manufacturing process have breathed new life into this ancient material. Now, slabs of raw clay are passed through metal dies, extruding them into long, uniform shapes, which are then fed into kilns by conveyor belts. These hollow extrusions are perfect for creating resilient rain screens and lightweight brise soleils. With customizable profiles and an assortment of colorful enamel glazes to choose from, it’s easy to see why architects still get fired up over terracotta.

© ikon.5 architects

School of Art & Design at New York State College of Ceramics by Ikon.5 Architects, Alfred, N.Y., United States

Terracotta by Boston Valley Terra Cotta

The School of Art & Design at New York State College of Ceramics was conceived “as a large ceramic container for holding art and light.” Inspired by both the program and Upstate New York’s rich history of manufacturing ceramics, the design features an irregular screen of terracotta tubes, which wraps around the upper floors, transforming the façade into a work of sculpture.

The hollow tubes, produced by Boston Valley Terra Cotta, are deliberately unglazed and colored only by an off-white pigment, which was mixed into the clay before firing. Their unfinished appearance and haphazard arrangement brings to mind the racks of student projects being worked on inside. The tubes also function as a brise soleil, protecting the south-facing galleries from direct sunlight. This shading strategy helped the project achieve LEED Silver certification upon completion.

Photographs of the Nembro Library via Ceramic Architectures

Nembro Library by Archea Associati, Nembro, Bergamo, Italy

Terracotta by Sannini

The Nembro Library is housed in two adjacent structures: a renovated building from 1897, which was first built as a kindergarten and was later converted into the town hall before being abandoned for several decades, and a contemporary addition shrouded in red tiles. The architects imagined this new building as a “triple-height bookcase,” with large expanses of glazing shaded by a screen of “terracotta books.”

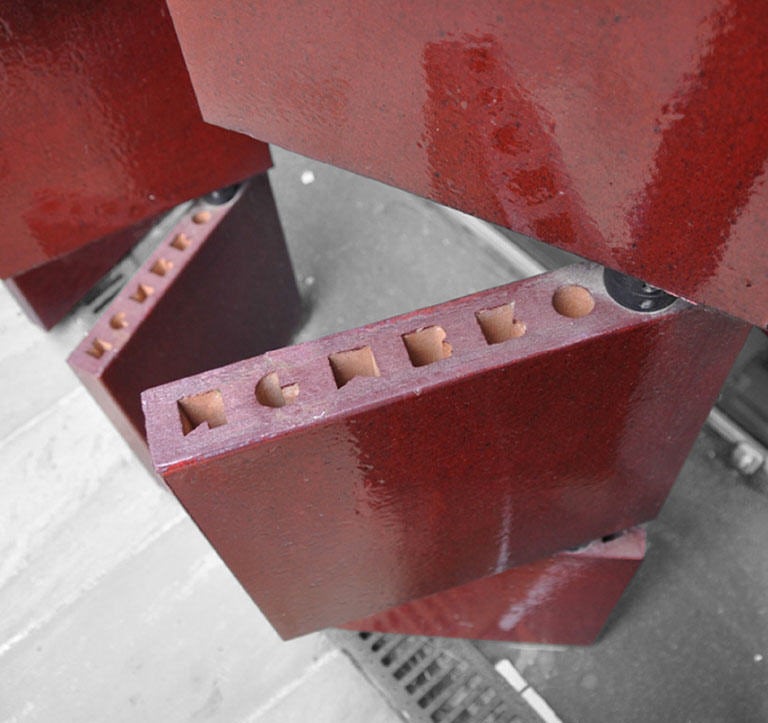

The screen is supported by a steel frame, painted red, with the tiles threaded onto rods and rotated to different angles. The tiles were finished with a carmine red enamel, which resonates beautifully with surrounding clay-tiled roofs. In fact, the terracotta was manufactured by Sannini, an Italian company that has been supplying the area with ceramic building products for over a century. In keeping with this local theme, each tile has an abstract N-E-M-B-R-O, the name of the town, extruded through it.

Detail of terracotta fins, image via BKSK Architects

Gatehouse to One Madison by BKSK Architects, New York, N.Y., United States

Terracotta by Boston Valley Terra Cotta

This modest building, discreetly located among historic row houses, is actually the entrance to a contemporary skyscraper, which soars 618-feet above the city streets. The restrained Gatehouse façade was designed to give residents “a sense of arriving home,” before ascending to their sky-high apartments. Its travertine cladding and bronze details blend in nicely with the neighboring limestone buildings, without feigning classicism.

Protruding from this façade is a rhythmic screen of terracotta fins, whose verticality draws eyes up toward the glass tower. Each fin was assembled from three pieces, a pointed end and two L-shaped caps, which conceal their aluminum substructure. The manufacturer, Boston Valley Terra Cotta, finished the fins with a cream-colored enamel, custom specified to shimmer in the morning sunlight.

© doublespace photography inc

Exterior and courtyard of the Albion District Library, photos via Archdaily

Albion District Library by Perkins+Will, Toronto, Canada

Terracotta by NBK Architectural Terracotta

The Albion District Library is a colorful oasis in a monotonous landscape of concrete and asphalt on the outskirts of Toronto. The architects, searching for a façade material that was both playful and durable, decided to clad the library in terracotta baguettes, manufactured by NBK Architectural Terracotta. The terracotta was finished with brightly colored glazes which make it resistant to water, sun fading, scratches and graffiti.

The solid portions of the building envelope are clad in a rain screen of glazed baguettes, fastened to a layer of unglazed baguettes, with boards of insulation sandwiched between them. Where more transparency is needed, the screen becomes a brise soleil. As the design director of Perkins+Will explained in an interview with Architizer: “The façade effectively transitions from a solid wall to an open screen of vertical colored tubes that enclose the courtyards and entry canopy. The terracotta baguettes allowed us to create that continuity as the building dematerializes from a mass to a floating veil.”

© Architekturfotograf Rasmus Norlander

© Architekturfotograf Rasmus Norlander

© Architekturfotograf Rasmus Norlander

Forfatterhuset Kindergarten by COBE, Copenhagen, Denmark

Terracotta by Creaton

Forfatterhuset Kindergarten is surrounded by old brick buildings in a historic Copenhagen neighborhood. The architects, wanting to “understand the area’s characteristics … but at the same time create something new and contrasting,” envisioned the school as a village of curvy brick “houses.” The various volumes are unified by ribbons of vertical terracotta bricks, known as lamellae, which wrap around the school, fencing in playgrounds and lushly planted green roofs.

The lamellae were custom fabricated by Creaton, using their patented KERALIS method. This involved firing the terracotta at extreme temperatures, nearing 2,200 degrees Fahrenheit, to create an extraordinarily high-strength and waterproof finish. The architects also worked closely with Saint-Gobain engineers to develop a flexible substructure, capable of supporting the lamellae while conforming to the uniquely curved buildings. You can learn more about the construction of this incredible façade here, in a video produced by Saint-Gobain.

Architects: Showcase your next project through Architizer and sign up for our inspirational newsletter.

Albion District Library

Albion District Library  Boston Valley Terra Cotta

Boston Valley Terra Cotta  Forfatterhuset Kindergarten

Forfatterhuset Kindergarten  Gatehouse to One Madison

Gatehouse to One Madison  School of Art & Design at New York State College of Ceramics

School of Art & Design at New York State College of Ceramics