Architizer's 14th A+Awards judging is live! Subscribe to our Awards Newsletter for updates on Public Voting and the big winner reveal later this spring.

Metal roofs have been used throughout history to stand the test of time. From the Romans who used copper as a roof covering for the Pantheon to alloyed metal roofs in European medieval architecture, these metallic structures are characterized by high resistance, impermeability and longevity. Modern standing seam roofs as we know them were developed in the 1960s and use metal as the roofing material instead of asphalt, tile or slate. Many options are available today, including aluminum, copper or aluminum-zinc alloy coated steel.

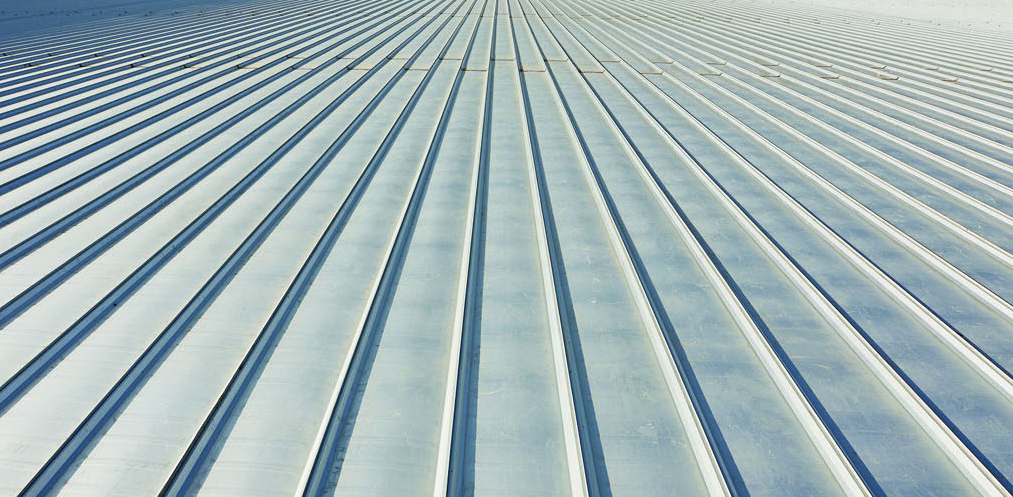

The term standing seam comes from the connections between the metal panels that are raised. The seams run vertically and are created by folding and crimping the edges between the panels. These roofs require minimal maintenance and provide both extreme resistance to high winds and a high fire rating. As a durable choice for roofing, we’re exploring the systems, materials and performance of standing seam roofs.

RHEINZINK angled standing seam

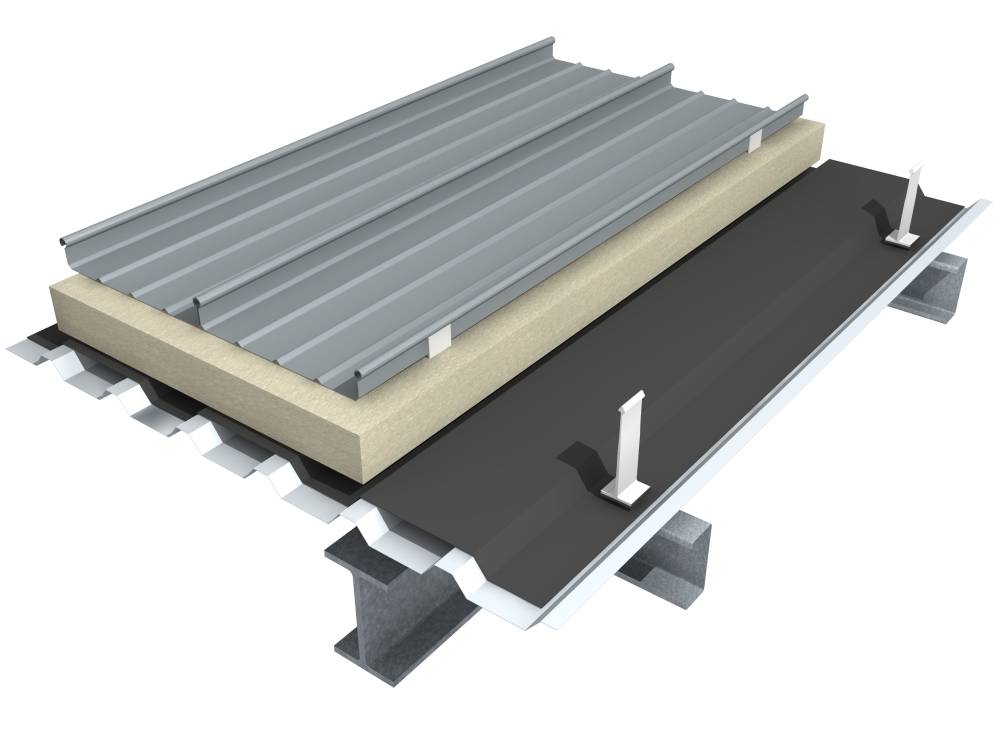

Systems

Standing seam roofs are available in several different types, with multiple methods of seaming and different metal used in manufacturing the roofing system.

Non-structural panel: A non-structural panel system uses two sections. One is the flat panel and the other is the batten or seam. The seam portion snaps into place over the clips protecting and concealing the fasteners. With the batten system, spacer clips are installed and locked into place. This type of standing seam metal roof must be installed over a solid substrate; it cannot be installed as a stand-alone or raised system. Tapered or curved panels are available.

Standing Seam Roof Diagram by Maerkang

Continuous seam positive locking: The continuous standing seam metal roof design uses an integral seam. Each panel is designed to snap into place over the previous panel and then it is fastened with clips. No seam caps are required and this reduces the potential for any creeping of the seam. Continuous seam systems can be directly fastened to a solid substrate. The positive locking installation reduces labor in the field.

Mechanically seamed in field: A standing seam metal roof system can be mechanically seamed in the field during installation. This system provides a variety of seam heights. Higher seams can add structural stability to the roofing system. Panels are installed with a fixed or sliding clip system. Sliding clips provide greater tolerance to temperature changes, as they slide during expansion and contraction. Mechanical seams done in the field also allow for curves using radius formation.

Shadow House by Matt Gibson

Materials

Standing seam metal roofs can be crafted in a variety of colors and materials. Lighter colors provide an added benefit of being cooler as they resist solar heat gain. Optimal materials for standing seam metal roofs are those that provide durability, corrosion resistance and longevity. Standing seam metal roof systems are available in different metals including aluminum, aluminum/zinc coated alloy, coated steel and copper. Choice of material is influenced by climate, aesthetic and budget; the following are among the most commonly specified options:

Aluminum: Aluminum possesses an excellent strength-to-weight ratio, meaning aluminum façade systems can be less bulky than those for steel panels. It is naturally resistant to rusting or blistering, making it a popular cladding choice for projects. Modern aluminum alloys can also support the weight of heavy glass spans, thus maximizing the building’s capability for using natural sunlight. The metal and its alloys are lightweight, durable, corrosion resistant and recyclable.

UCONN Social Science East Building Storrs

Copper: Another common standing seam cladding option is copper, which is very durable compared to other materials, and at the end of the building life is also 100% recyclable. Its subtly reflective appearance evolves over time due to oxidization, turning the metal a distinctive green color.

Coated Steel / Zinc: While standing seam roofs can use a variety of different types of coating, a common type is galvanized steel which uses a thin layer of zinc. This helps to prevent rusting in a similar manner to chromium in stainless steel. Visible crystallites in the coating give galvanized steel a mottled aesthetic feature known as “spangle”.

Shurkin Addition by Casey Hughes Architects, Los Angeles, Cali. Image via Casey Hughes Architects

Performance

Standing seam metal roofing systems are installed over an insulating material for added energy efficiency. This insulation also reduces the noise problems that may be found in some metal systems. Standing seam metal roofing systems are normally used for roof slopes of 3:12 or greater. This roofing system does not use exposed fasteners; the raised seams interlock tightly and prevent water penetration.

Mounting options: One of the best parts about standing seam is the option to mount items, such as solar panels, snow retention systems, swamp coolers, or other rooftop addition, without ever having to penetrate or make any holes in the surface of the roof.

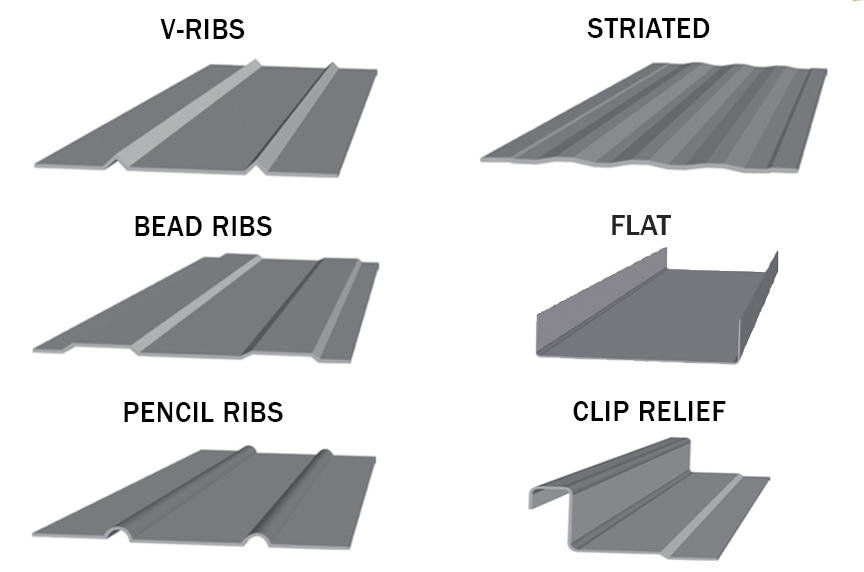

Rib Rollers by Sheffield Metals

Durability: Properly installed standing seam metal roofs will last 2-3 times longer than lighter gauge, screw down metal roofing. Not only is the metal itself thicker, 24 gauge compared to lighter grade metals 29 gauge, the paint is also much better. Most standing seam metal roofing is given color with kynar paint that last 35 years.

Wind Action: Building cladding systems are required to sustain wind actions and transfer them to the main building structure. The guidance given in chapter 30 of the ASCE 7-10: Minimum Design Loads for Buildings manual can be used to determine the natural wind actions to be considered during the design of cladding.

Expansion & Contraction: Some metals contract and expand with changes in temperature, humidity and pressure, and if the wrong material is specified, this can lead to permanent building damage. Consult with your manufacturer to establish which standing seam product is most appropriate for the climate in which your project is to be located.

Fire resistance: Standing seam metal is generally very resistant to fires, but it is still advisable to consult with manufacturers on the fire-resistance rating requirements of standing seam roofs. It is also important to consider how the standing seam relates to other materials within a building envelope to avoid unforeseen consequences.

Moose Road by Mork-Ulnes Architects

Cost

A standing seam metal roof usually costs more than other types of metal roofing. It’s important to understand the life cycle, where a steel roof with an aluminum-zinc alloy coating can easily last up to 100 years. When considering the cost of standing seam versus other roof systems, understand the implications of exposed screws, maintenance over time, and how well a roof keeps water out.

Exposed Screws: Metal roofing that screws down requires on average 70 exposed screws per sq. of roofing. On an average sized home this can add up to something like 2,500-3,000 screws or 3,000 potential leaks down the road. Standing seam metal roofs do not have this problem, as the metal is held down with clips that are underneath the metal panels. This means the screw is hidden and should not have a leak issue, and the clip is secured to the roof and not the standing seam metal roofing panel which allows the metal roofing to go through its daily expansion and contraction.

Clicklock Premium Standing Seam

Watertight: Standing seam is a metal roofing system that is designed to interlock to itself keeping water out. The standing seam metal roofing panels are flat in the pan and can be bent to create a hem. The hem is then slid onto a cleat which is sealed with butyl tape when attached. The result is roofing details that are water proof for long term.

Maintenance: Because the roofing details of standing seam around chimneys, skylights and valleys are interlocking and do not rely on caulking, they are very low maintenance. Light gauge metal roofing panels that cannot be hemmed will routinely need sealants around important areas to stay leak free.

Case Studies

With different systems and materials available, the following case studies can help further inform how architects understanding standing seam roofs and their specification. From individual projects to collections and precedents, the following examples help illustrate how standing seam and metal roofs can be applied in modern works of architecture.

Columbus Museum of Art, Margaret M. Walter Wing by DesignGroup, Columbus, Ohio

Columbus Museum of Art, Margaret M. Walter Wing by DesignGroup, Columbus, Ohio

The architect chose to sheath this 50,000-square-foot wing of the Columbus Museum of Art with pre-patinated copper, in a sense using a time-honored material in a contemporary way to both counter and complement the bronze detailing of the historic wing as well as reference the nearby First Congregation Church’s naturally oxidized copper roofs and spires. The copper cladding is also found in the building interiors. The wall panels are rainscreen products engineered and fabricated by Keith Panel Systems using pre-patinated sheets from Zahner. Zahner also fabricated the custom flashing and standing seam roof.

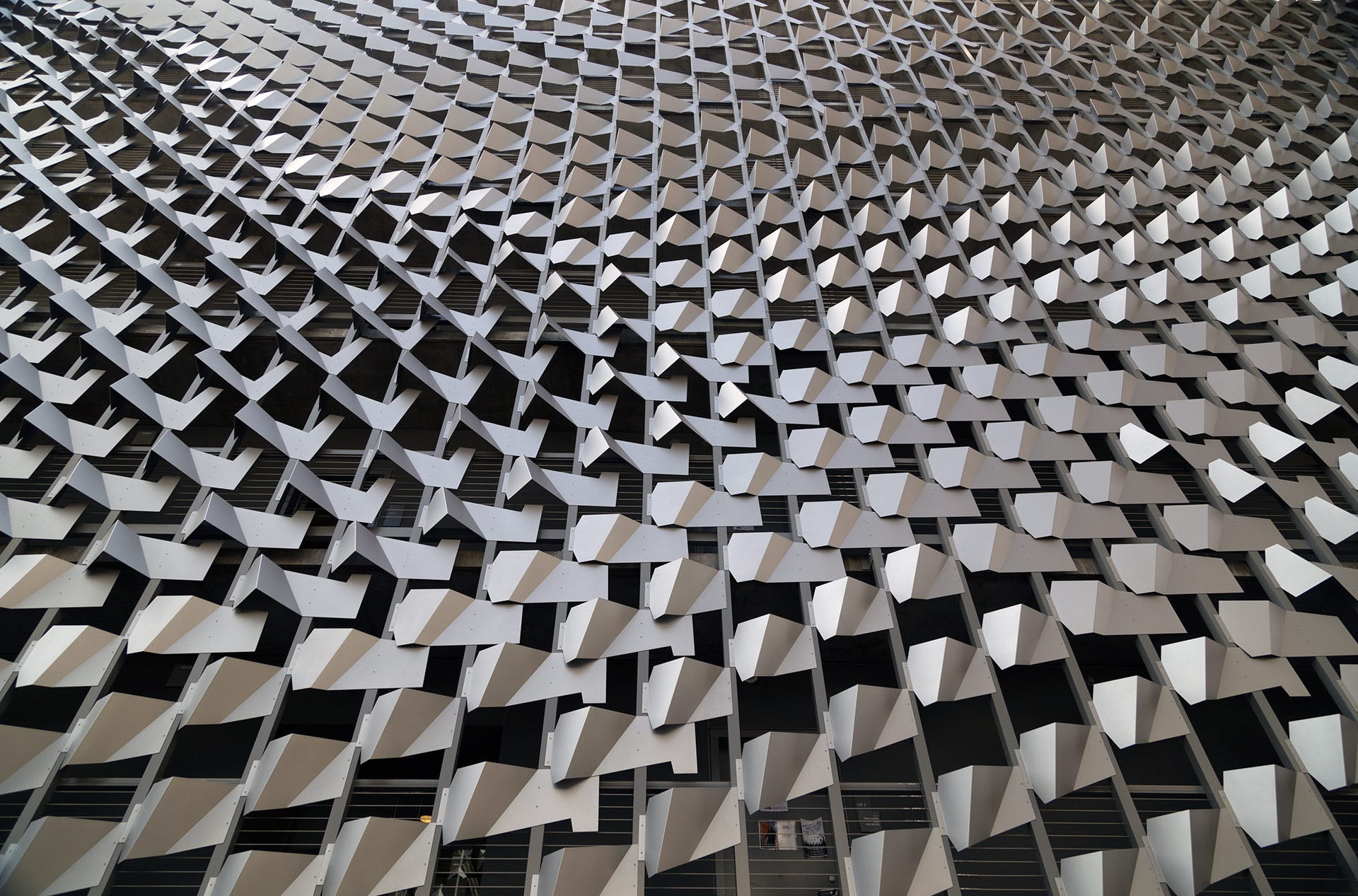

Pushing the Envelope: 7 Bold Buildings Clad in Metal

Pushing the Envelope: 7 Bold Buildings Clad in Metal

Metal cladding dramatically alters the dynamic of a building. In its rawest forms, it’s flexible, durable and economical. On much grander scales, and ever since Frank Gehry’s Guggenheim Museum in Bilbao catapulted onto the global stage, the architecture world has seen a steady push forward in massive metal façades. Both visually remarkable and pragmatic, the material’s qualities and applicability are undeniable. These seven projects explore metallic façades, skins and building envelopes that are particularly fascinating.

Klammer Residence by architektur.terminal hackl und klammer, Austria

Klammer Residence by architektur.terminal hackl und klammer, Austria

By way of cladding the architects chose pre weathered pro Rheinzink panels in a dark-slate pickled finish. They are mounted by the angled standing seam method where the joints stand out for aesthetic effect. The horizontal seam-lines are at irregular distances, which breaks up yet lends movement to the otherwise uniform surfaces of these walls, an at the same time picks up the horizontal motif of the ribbon windows.

Soda Pop Design: 7 Clever Architectural Details in Aluminum

Soda Pop Design: 7 Clever Architectural Details in Aluminum

In construction applications, aluminum first appeared in roofing, flashing, wall panels and spandrels. The first extensive use of aluminum in construction occurred in the Empire State Building. As a material, aluminum also possesses an excellent strength-to-weight ratio, meaning aluminum façade systems can be less bulky than those for steel panels. Exploring aluminum architecture and its detailing, this collection of projects showcases how some of the world’s most innovative architects have utilized aluminum in modern construction projects.

Architizer's 14th A+Awards judging is live! Subscribe to our Awards Newsletter for updates on Public Voting and the big winner reveal later this spring.

Columbus Museum of Art

Columbus Museum of Art  Klammer Residence

Klammer Residence