Architizer is thrilled to announce that the 2026 A+Product Awards is open for submissions! The clock is ticking — get your products in front of the AEC industry’s most renowned designers by submitting today.

Materials are the basis of all architecture. Terms like wall, roof and floor are abstract concepts — it’s what they’re made of that matters. While those terms and concepts rarely change, though, the materials that comprise them have evolved considerably over the years. As such, the history of building materials is a history of trial and error. Each step comes with lessons learned and improvements made.

As today’s era of building pushes on with an ever-expanding array of high tech and experimental materials, it’s worth looking back at where we’ve been. Some of the materials below have been gone for awhile, and it’s important for today’s young architects to remember why they were phased out in the first place. Other materials are still around in some form, but losing ground to something better, less resource-intensive or simply cheaper. Take note — and hopefully find some inspiration for your own projects, as well.

Via Pure Plastering and Insofast

Plaster vs. Gypsum Wall Board

Perhaps the most common of architectural elements, the interior partition, as it’s known by most people today, is materially quite different than it has been historically. Prior to the mid-20th century popularization of Gypsum Wall Board (GWB), especially in North America, most interior walls were made from spreading wet plaster on lath or metal mesh. GWB, a mixture of gypsum and other additives pressed between layers of paper, completely supplanted plaster in the mass market for the simple fact that it’s cheaper and easier to install, though plaster is still used occasionally to shape difficult curves or for some high-end, luxury applications.

Via Cleveland and Home Depot

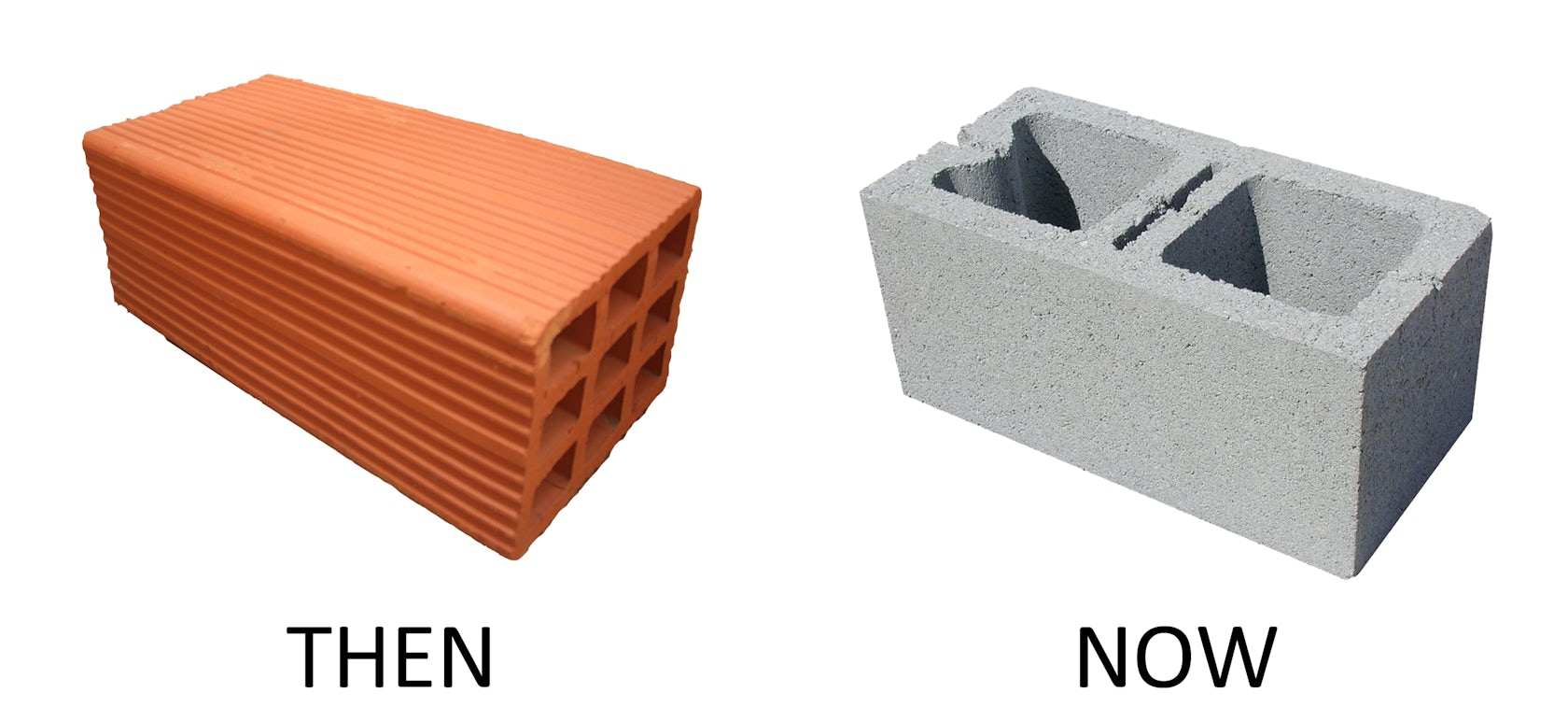

Terra Cotta Block vs. Concrete Masonry Units

For a long time, hollow, clay-tile blocks were used for structural and non-structural framing in many buildings. While they continue to be used in parts of Europe, in most of North America they were replaced by the similarly hollow, though possibly less visually appealing, Concrete Masonry Unit (CMU) in the mid-20th century. The transition seems to have been driven by a combination of economics and availability, though terra cotta blocks are still noted for their comparatively light weight, thin profile and inherent fire resistance.

Via Haunn Black House and Sabine’s New House

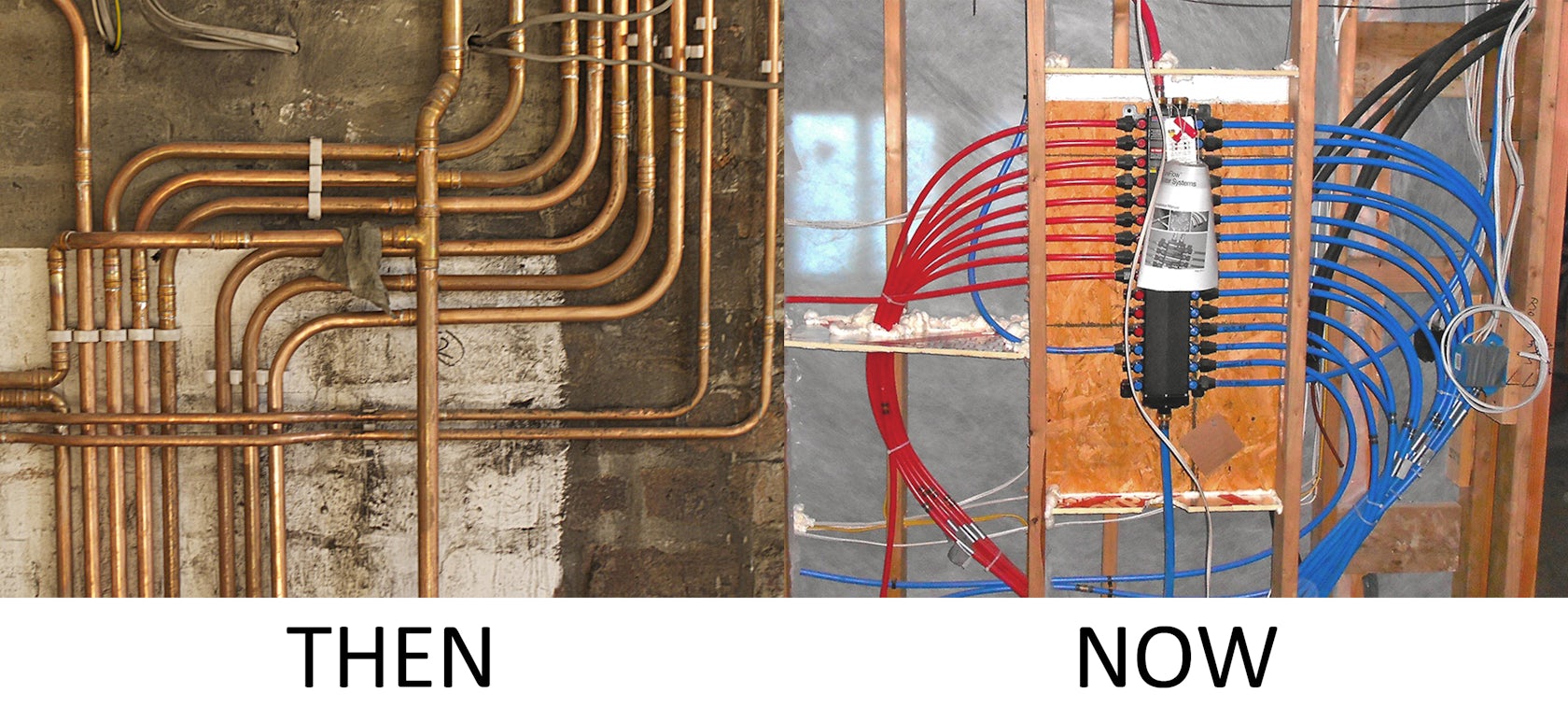

Copper Piping vs. Cross-Linked Polyethylene

Copper pipes are by no means a thing of the past, but their popularity is starting to wane due to the metal’s high cost. A viable replacement that’s increasing in popularity is cross-linked polyethylene (PEX), a flexible, manufactured tube that can be used in place of traditional rigid pipes to supply hot or cold pressurized water. PEX offers many advantages, including ease of installation and maintenance, light weight, a low thermal conductivity that results in energy conservation, and the elimination of “water hammer” — the common household noise rigid pipes make when water pressure forces them to jump suddenly.

Via The Spruce and Wikipedia

Asbestos Insulation vs. Mineral Fiber Insulation

There are many, many different materials available for use as building insulation, and while choosing the appropriate one is often a trade-off between several factors, one type that’s no longer available is asbestos-containing insulation. Banned or limited by many countries in the late 20th century, asbestos was found to cause a host of deadly health problems, including lung cancer, as friable bits of it could be released into the air as dust and breathed in by people. While a wide range of available insulation types ensures there was no single, go-to replacement for asbestos-containing insulation, mineral fiber insulation is often a superlative choice for its typically high percentage of recycled content and variety of application types.

Lead-based Paint vs. Titanium or Zinc-based Paint

Similar to asbestos’ history in building materials, lead-based paint was used widely, at least in the United States, until its ban in household applications in 1978. Exposure to lead-based paint can cause damage to the brain and nervous system, thus paint manufacturers were forced to replace lead with titanium or zinc pigments that offered similar benefits, such as a shortened drying time, attractive appearance and moisture resistance. Like insulation, there are many options to choose from when specifying paint these days, and while each project will have its own factors to account for, a key consideration when choosing paint is the level of Volatile Organic Compounds (VOCs) it contains — the less, the better.

Via Chidaneh and JJT Travels

Ancient Rammed Earth vs. Contemporary Rammed Earth

Rammed earth construction fell out of favor long ago with the advent of bricks and other unitized lode-bearing materials, but it seems to be making a comeback lately due to modern construction techniques and its sustainable properties. Since rammed earth for buildings is usually taken from the project site itself, transportation costs are essentially zero, while modern construction tools allow it to be formed and compacted far more effectively and efficiently than the ancient tools it used to be worked with. Paired with natural insulative properties, contemporary rammed earth construction could be a great choice for relatively small, single-story buildings, its only major drawback being the labor-intensive process needed to form it.

Via Pinterest and Nina Dinoff

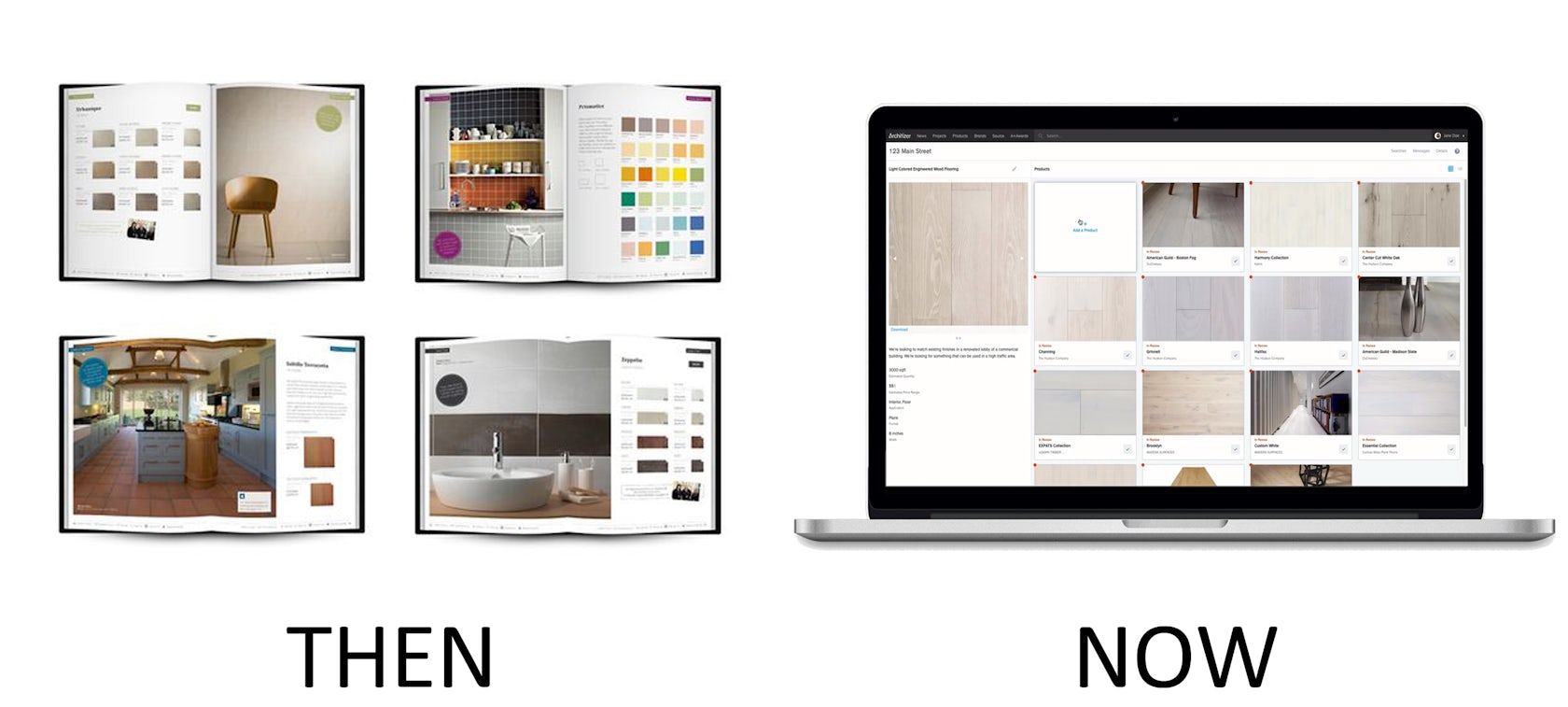

Bonus: Choosing vs. Specifying

Before a material can be used, it must be selected. To that end, the history of architects picking construction materials is an interesting one. Prior to the first publication of the once-ubiquitous Sweets Catalog in 1906, architects relied on uncoordinated catalogs from a wide range of product manufacturers. Sweet’s eventual synchronization with the CSI numbering system was a help, but curiously enough, the rise of the internet and Googling for building-products seems to have brought architects back to the de-centralized, pre-Sweets practice of browsing through manufacturer’s information themselves. Now, platforms like Architizer are bringing that process back into one place again — albeit a digital one.

Architizer is thrilled to announce that the 2026 A+Product Awards is open for submissions! The clock is ticking — get your products in front of the AEC industry’s most renowned designers by submitting today.