Fire extinguishers are rarely a detail that excites architects and designers — if they are even factored into the design process. As afterthoughts, they are clunky and disrupt the smooth lines and exciting details of spatial design. As forethoughts, their shape often requires deeper wall cavities that are expensive, both in materials and the usable square footage they require.

Kevin Kozlowski, who spent 20 years as a project manager for one of the largest contractors in the U.S., noticed the issue of fire-extinguisher placement was causing construction problems and occupancy issues. “I was constantly seeing blueprints where architects added notes for a flush extinguisher cabinet on a standard-depth wall — but a standard fire extinguisher cannot fit into a standard-depth wall,” Kozlowski recalls. Round commercial-sized extinguishers cannot fit into fully recessed cabinets when walls are framed with studs which measure 3⅝ inches, and over 90 percent of commercial walls are built to that depth. Once the problem was identified, the architect would either settle for a semi-recessed cabinet, or the wall design would be revised to 6 inch studs to allow a flush cabinet to fit. If discovered late in the project schedule, sometimes walls were torn down and rebuilt, followed by contentious change orders. In expensive real-estate markets, those changes matter: When extinguisher cabinets require 6-inch studs, each extinguisher and cabinet cost the client a minimum of 3 square feet of space. Semi-recessed cabinets often leave a bad taste in the designer’s mouth, but the deeper wall solution is often worse, as its effects bleed across an entire project.

As a lifelong inventor and self-professed “tinkerer,” Kozlowski was certain there was a solution to the problem that had plagued nearly every job site of his construction career. While it seemed like a basic issue with a straightforward solution, it was, in fact, a complicated one.

Optimal engineering practices and simple tensile strength lead the design of pressure vessels toward a form which is round. “The most efficient ways to hold pressure is spherical or cylindrical, and vessels holding pressure that aren’t round want to be round,” he explains. Even if he could design a non-round vessel, it would have to pass UL testing standards, which includes withstanding a test pressure of 1,560 pounds per square inch. This test is eight times the standard operating pressure of an ABC fire extinguisher (195 psi). If Kozlowski was going to solve this issue, he had to take a dual-pronged approach.

Can we make a pressure vessel that will pass UL testing as well as fit in a recessed wall?

Kozlowski was still weighing efficacy, market demand and the engineering challenges of his new design as he swung by a local wholesale club to pick up weekend supplies for the family. As he wound his way through the aisles, he noticed something that took him by surprise: All the fire extinguishers were in violation of the American Disabilities Act (ADA). As soon as the bottom of an object is 27 inches off the floor, it cannot protrude more than 4 inches from the wall into a pathway. The ADA was the first code he noticed, but his observation also applied to local accessibility standards, ANSI, the International Fire Code and almost all other local building codes.

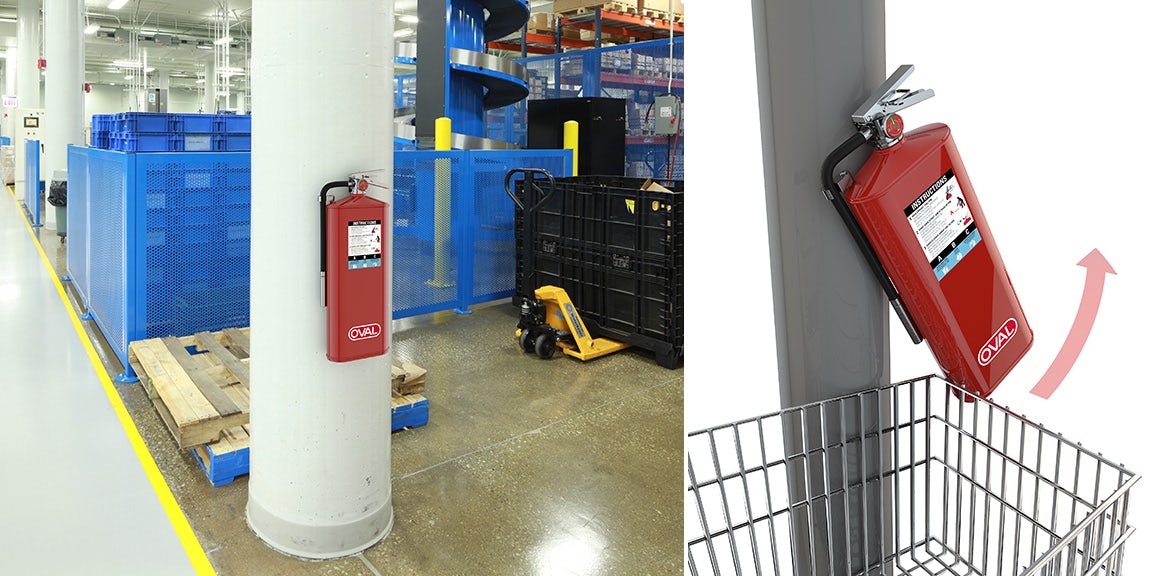

“As I was walking through the store, I saw their extinguishers installed with the bottoms located at 44 inches off the ground,” Kozlowski says. “And I realized I had invented a way to resolve the ADA and code issues — and more. Our fire extinguishers never protrude more than 4 inches when surface mounted.”

1. Oval Brand’s fire extinguishers are the only solution that lets you use a fully recessed cabinet within a standard wall.

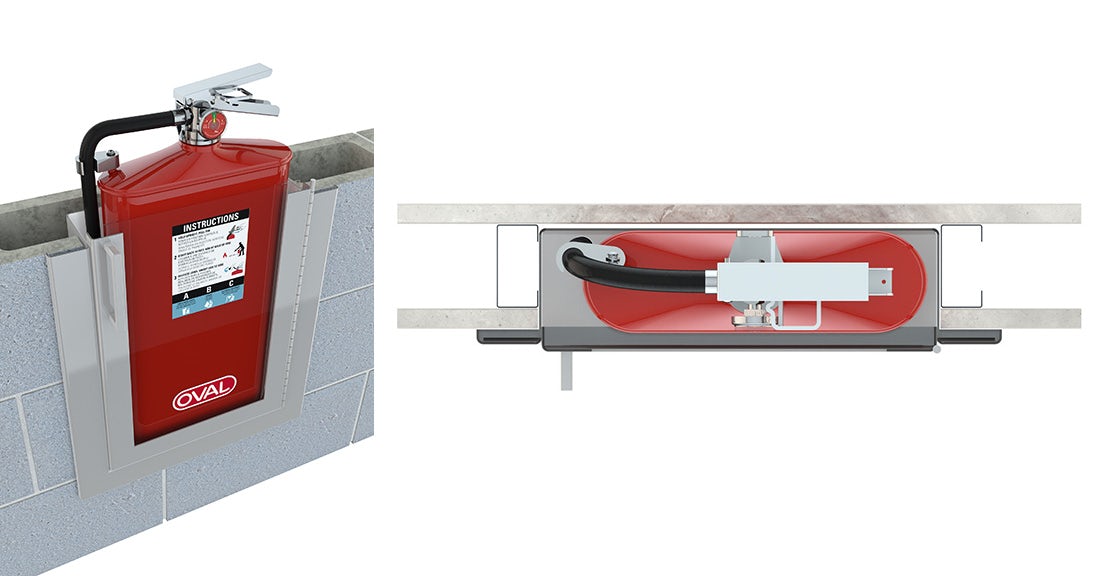

Two 10-pound ABC models are currently available: Model J measures 3 inches deep and Model H measures 3½ inches deep. Model J can fit comfortably in a fire-rated recessed cabinet within the confines of a 3⅝-inch wall cavity. In a standard, non-rated cabinet, fully recessed cabinets can now fit into 2½-inch studded wall cavities and 6-inch masonry. Standard and fire-rated recessed cabinets are also available through Oval, JL Industries and Strike First Corporation of America. Model H is best for surface mounted installations.

2. These products are also cheaper, greener and more elegant in design.

While the oval shape is more costly to manufacture up front, it presents greater savings throughout a design project. Fully recessed cabinets are not only flush with walls, they are also designed so Oval Fire Products extinguishers fit snugly within the studs, requiring few additional installation requirements. For commercial developers and architects, Oval Fire Products save 3 feet of space, or more, per extinguisher. To put this in perspective: In the Chicago Loop where rent is $35 per foot, developers can save $550 per extinguisher; in Lower Manhattan where rent is $280 per foot, that space efficiency equates to saving $1,500 per year. Plus, by keeping walls at the standard depth, the recovered square footage may be included within a tenant’s lease, thus providing the building owner with additional annual earnings as well. This approach maximizes usable square footage and uses less material.

3. Oval Brand fire extinguishers always comply with the ADA’s protruding object limits.

No other manufacturer of fire extinguishers in the common commercial sizes can make this claim. Oval has been awarded multiple patents for their innovative pressure vessel technology.

One should also consider that ADA compliance isn’t just to accommodate wheelchairs. It also protects end users with vision problems and mobility issues. Often the greatest beneficiaries of the ADA design guidelines are people without disabilities, such as parents with strollers who use the ADA automatic door openers. These guidelines provide a larger benefit to society as a whole.

4. Oval products also comply with the Life Safety Code.

In healthcare settings that receive Medicaid or Medicair funding — be it hospitals, rehabilitation facilities, hospices or senior living centers — anything located in corridors at a height below 38 inches or an existing handrail cannot protrude from a wall beyond 4½ inches. Installed as a surface mount, Oval Brand fire extinguishers are the only products that always comply with the NFPA 101 Life Safety Code (per the 2012 edition).

5. Oval extinguishers feature the best hook on the market.

Because of its slim profile, Model H and Model J extinguishers are ideal solutions for surface mounting. In addition to ADA compliance, Oval is one of the safest solutions thanks to its uniquely designed patented hook. “When you bump ours, it swivels instead of falling off,” Kozlowski says. “In our opinion, the industry’s standard hooks are lousy, so when I started designing the non-round pressure vessel, I wanted to look at all the problems I could solve — and that included all those settlement checks retailers issue for extinguishers that fall off walls and injure customers.” An Oval Brand fire extinguisher may cost slightly more than standard cylindrical units, but they greatly reduce the risk of an ADA lawsuit or injury claims.

If you strive to do better for your clients, Oval Brand Fire Products is poised to help you achieve that goal by prioritizing innovation, safety and design over