Architects: Want to have your project featured? Showcase your work by uploading projects to Architizer and sign up for our inspirational newsletters.

While it’s long been a part of iconic soda cans, aluminum hasn’t always been a popular material within the built environment. The metal was expensive and generally not harnessed for architectural use until the early 20th century. Use of aluminum in buildings increased in the 1920s, primarily for decorative detailing. In construction applications, aluminum first appeared in roofing, flashing, wall panels and spandrels. The first extensive use of aluminum in construction occurred in the Empire State Building (1930-1932). Parts of the tower structure and spire are built from aluminum, as well as components such as the entrances, elevator doors, ornamental trim and more than 6,000 window spandrels.

As a material, aluminum also possesses an excellent strength-to-weight ratio, meaning aluminum façade systems can be less bulky than those for steel panels. Modern aluminum alloys can also support the weight of heavy glass spans, thus maximizing the building’s capability for using natural sunlight. The metal and its alloys are lightweight, durable, corrosion resistant and infinitely recyclable. Nearly 75 percent of all aluminum produced is still in use today.

Exploring aluminum architecture and its detailing, we’ve gathered a collection of projects that showcase how some of the world’s most innovative architects have utilized aluminum in modern construction projects.

Balancing Barn by MVRDV, Thorington, UK

Aluminum Manufactured by Reynaers Aluminum

Balancing Barn is situated on a beautiful site by a small lake in the English countryside near Thorington in Suffolk. The Barn responds through its architecture and engineering to the site condition and natural setting. The traditional barn shape and reflective metal sheeting take their references from the local building vernacular. In this sense the Balancing Barn aims to live up to its educational goal in re-evaluating the countryside and making modern architecture accessible.

At the midpoint the Barn starts to cantilever over the descending slope, while the structure balances on a central concrete core, with the section that sits on the ground constructed from heavier materials than the cantilevered section. The long sides of the structure are well concealed by trees, offering privacy inside and around the Barn. The exterior is covered in reflective metal sheeting, which, like the pitched roof, takes its references from the local building vernacular and reflects the surrounding nature and changing seasons.

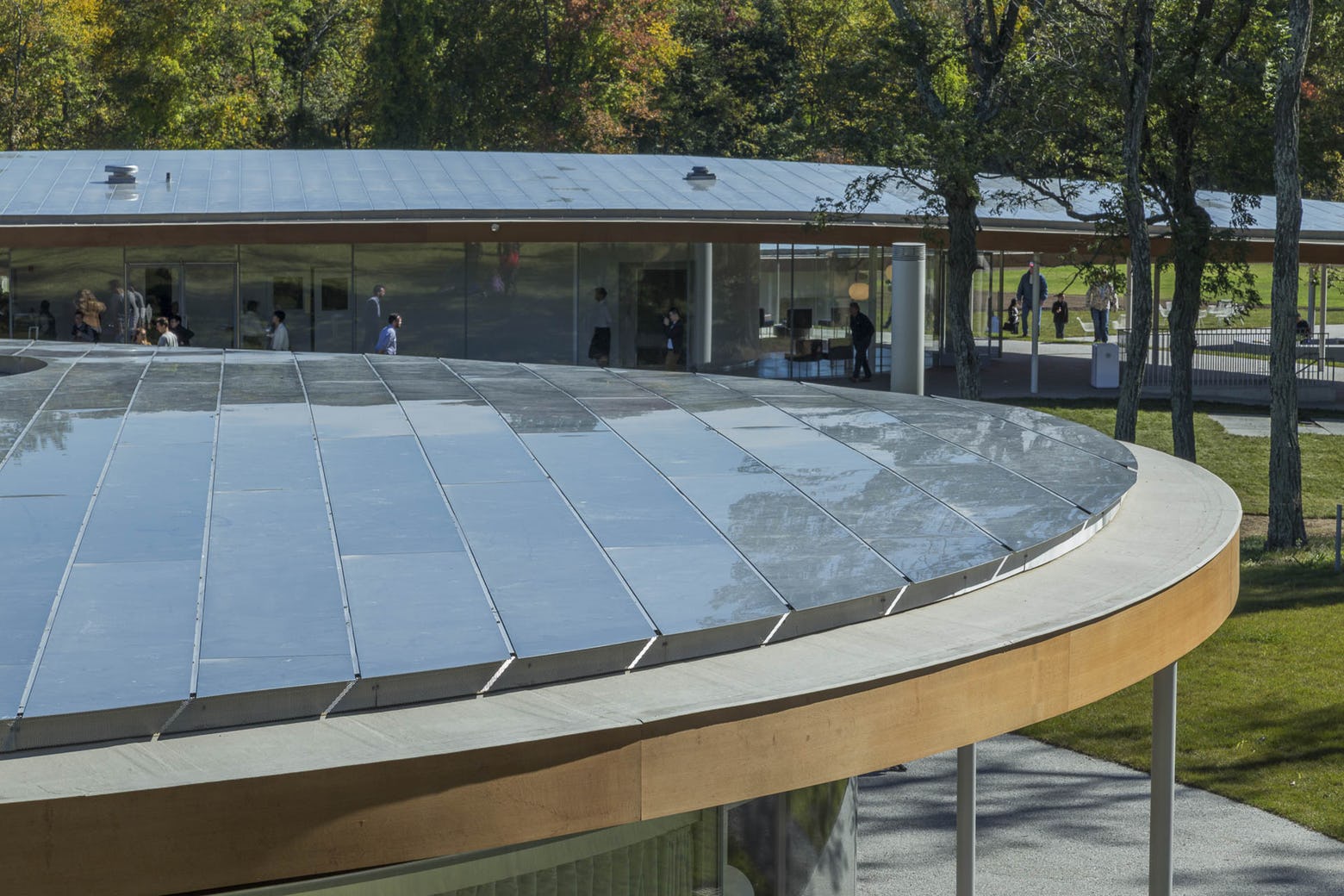

Grace Farms by SANAA, New Canaan, Conn.

Aluminum Rainscreen Roof manufactured by Zahner

Located in New Canaan, Connecticut, the multipurpose building and landscape project was made with Handel Architects to embrace open space for people to experience nature, encounter the arts, pursue justice, foster community and explore faith. SANAA was inspired by the idea of making the architecture a river that’s part of the landscape, an element that doesn’t draw attention to itself. The result is a simple, elegant building that rethinks the relationship between architecture and landscape.

The Grace Farm’s River project floats as a ribbon of glass and steel above the hilly landscape. Working with Zahner, SANAA wanted to give life to the idea of a building that’s part of nature. The structure combines a sanctuary, library, court, commons, and pavilion under an aluminum roof. Featuring a dual curvature panel system, the roof design consists of standard-sized sheets of exterior anodized aluminum. The project uses a light-weight system to achieve the shape with several custom aluminum extrusions that form a channel between the aluminum skins. Here, a floating aluminum plate provides a visual transition between panels.

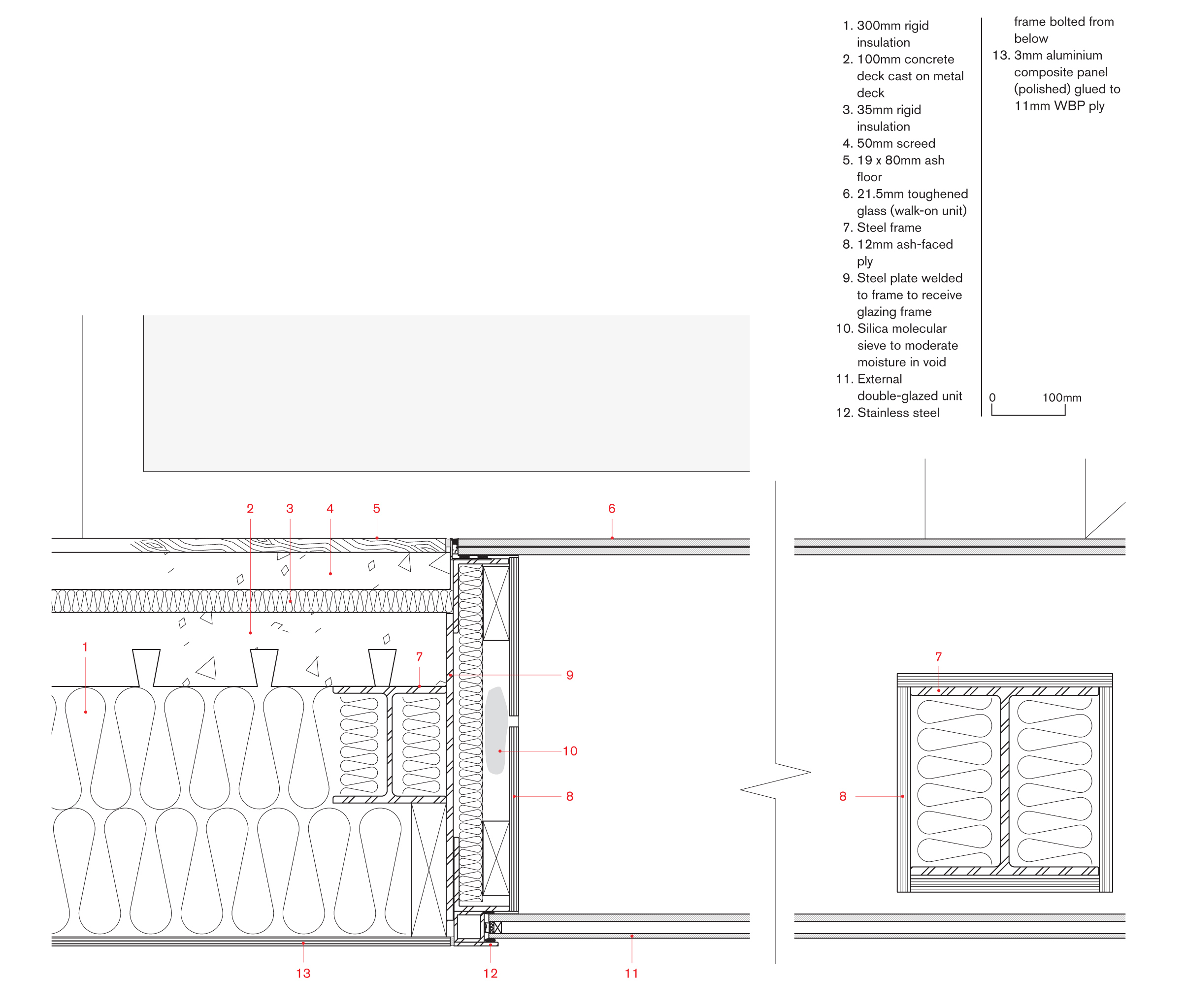

Mayfair House by Squire and Partners, London, UK

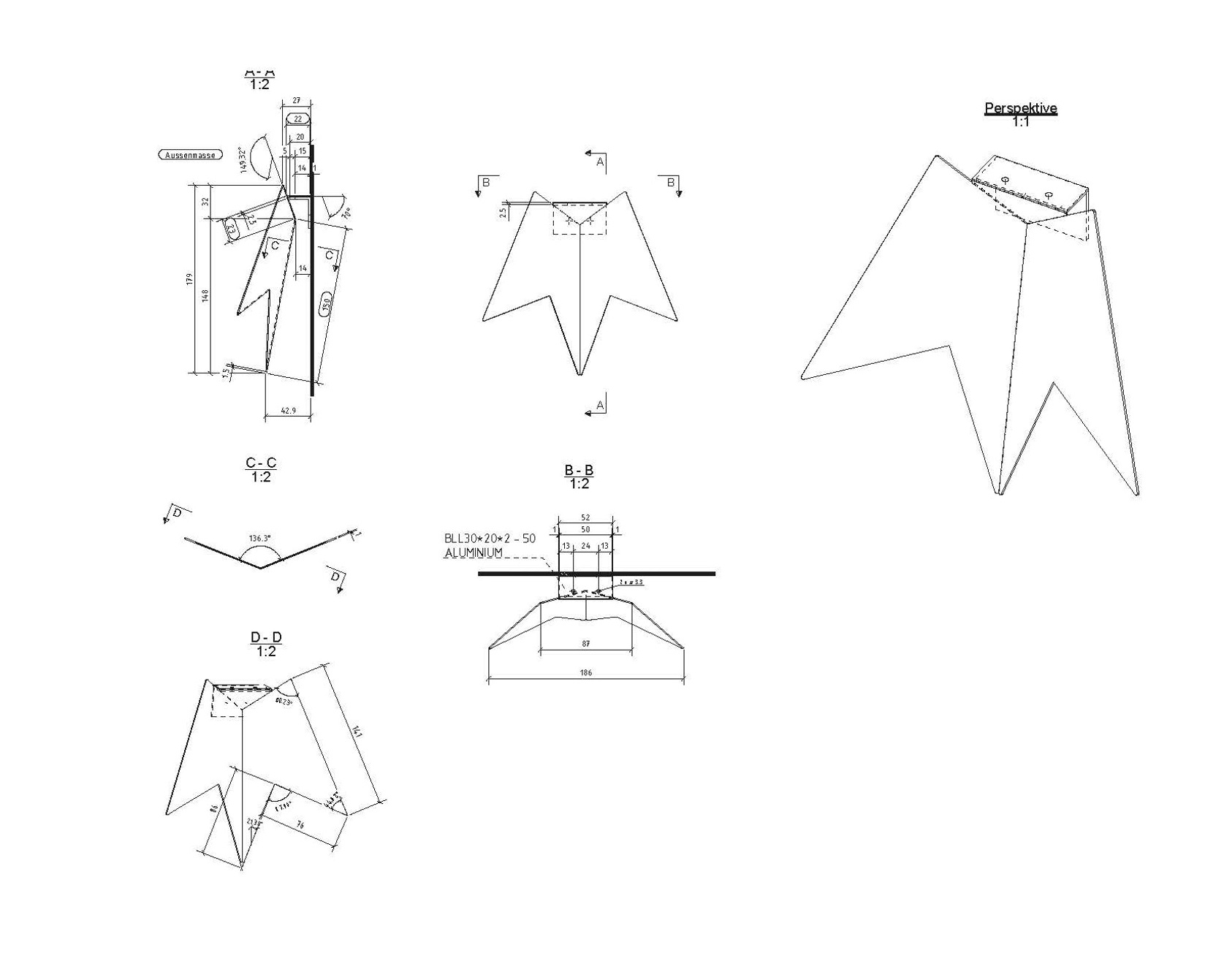

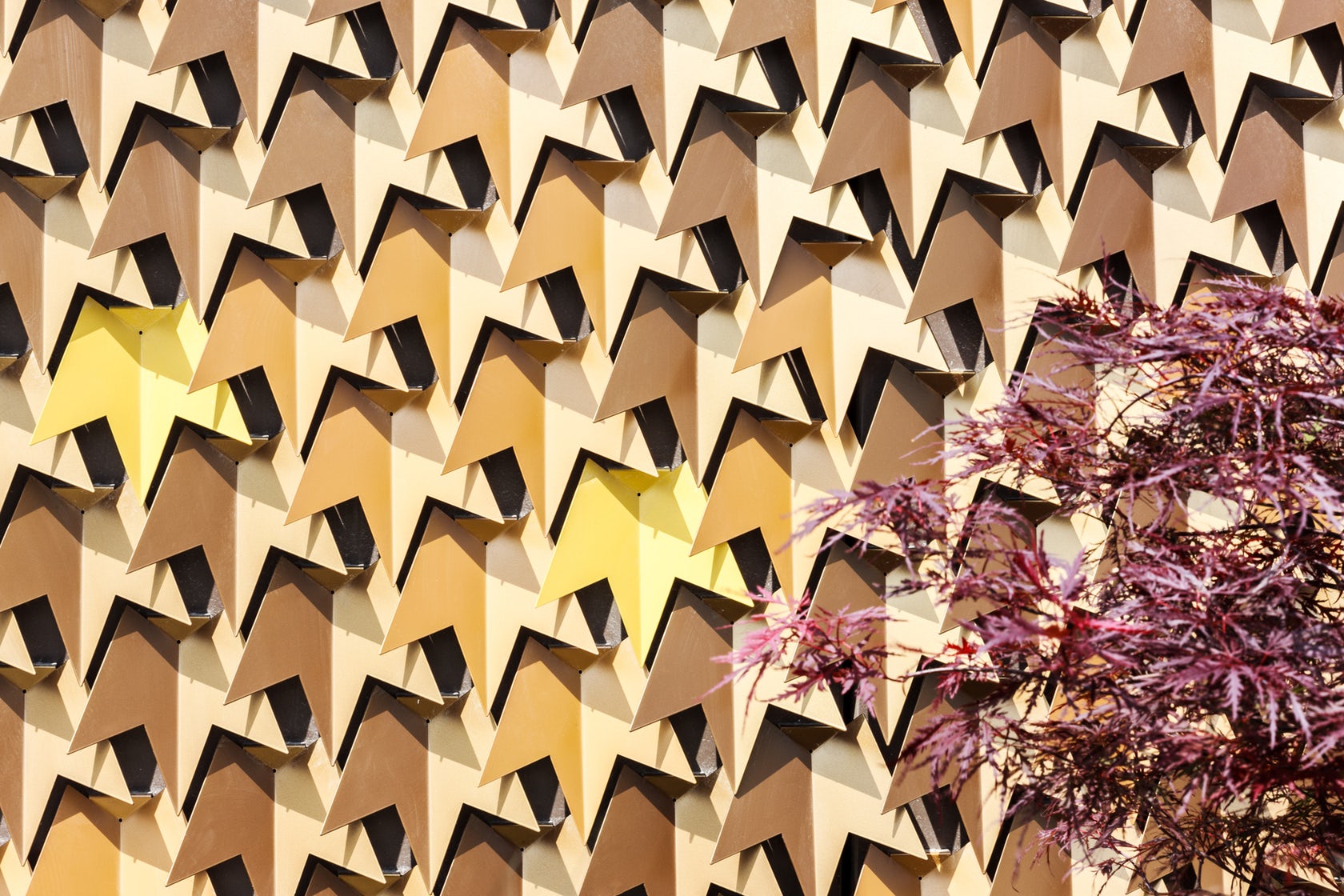

Aluminum Manufactured by Tuchschmid AG

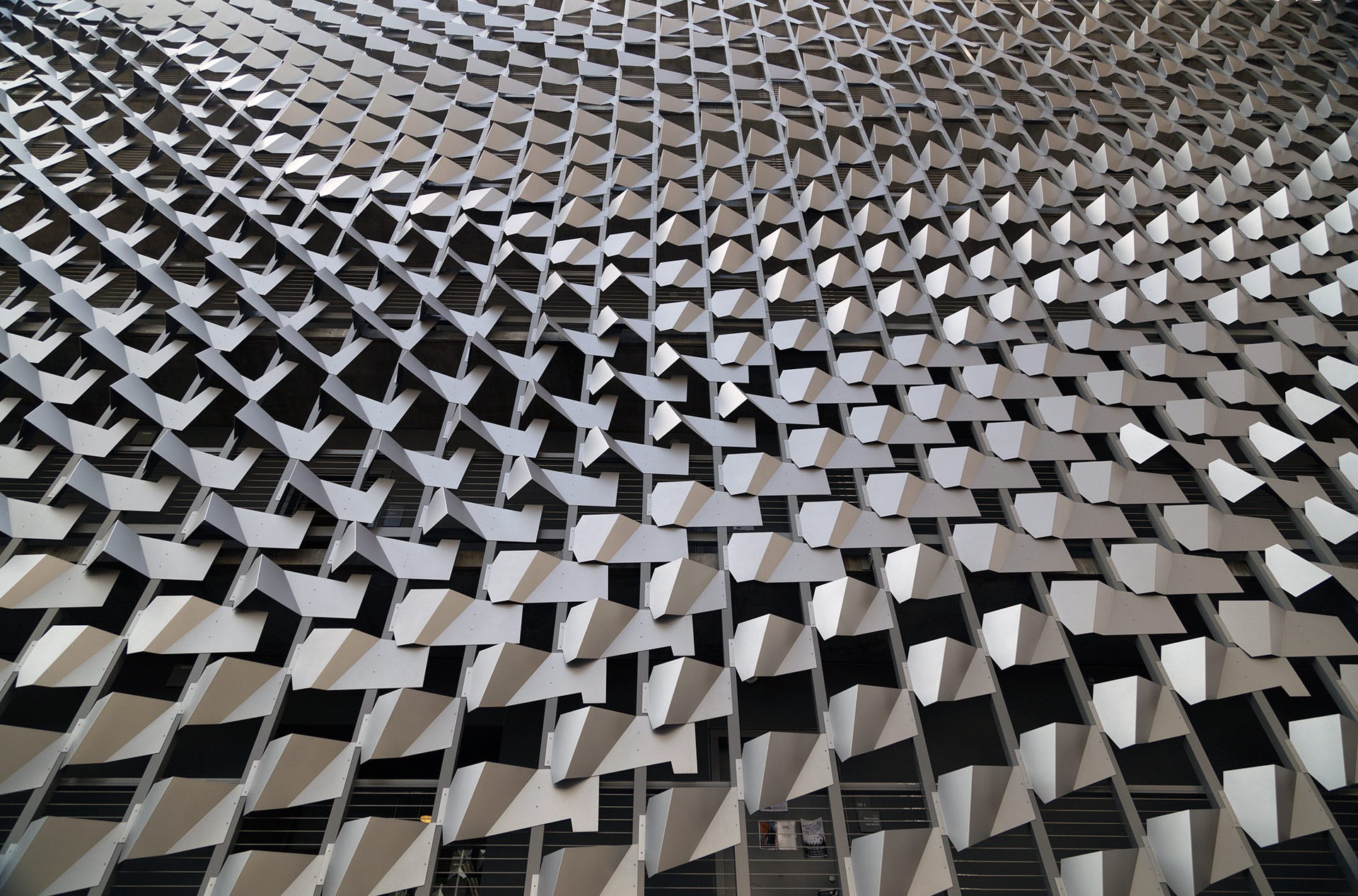

Squire and Partners have completed a private house in Mayfair, London, featuring a striking bespoke leaf facade which mirrors an established Virginia Creeper on a facing building on Curzon Street. Westminster planning committee described the proposal as “striking” and “raising the bar for design within the borough.”

The contemporary interpretation of leaves are crafted as a metallic shingle, which cover a three story elevation and rooftop pavilion. The PPC-coated folded aluminum leaves — 4,080 in total — subtly vary in tones of bronze to mimic organic growth patterns. The concept was designed over a three-year period of research and development working closely with Swiss manufacturer Tuchschmid.

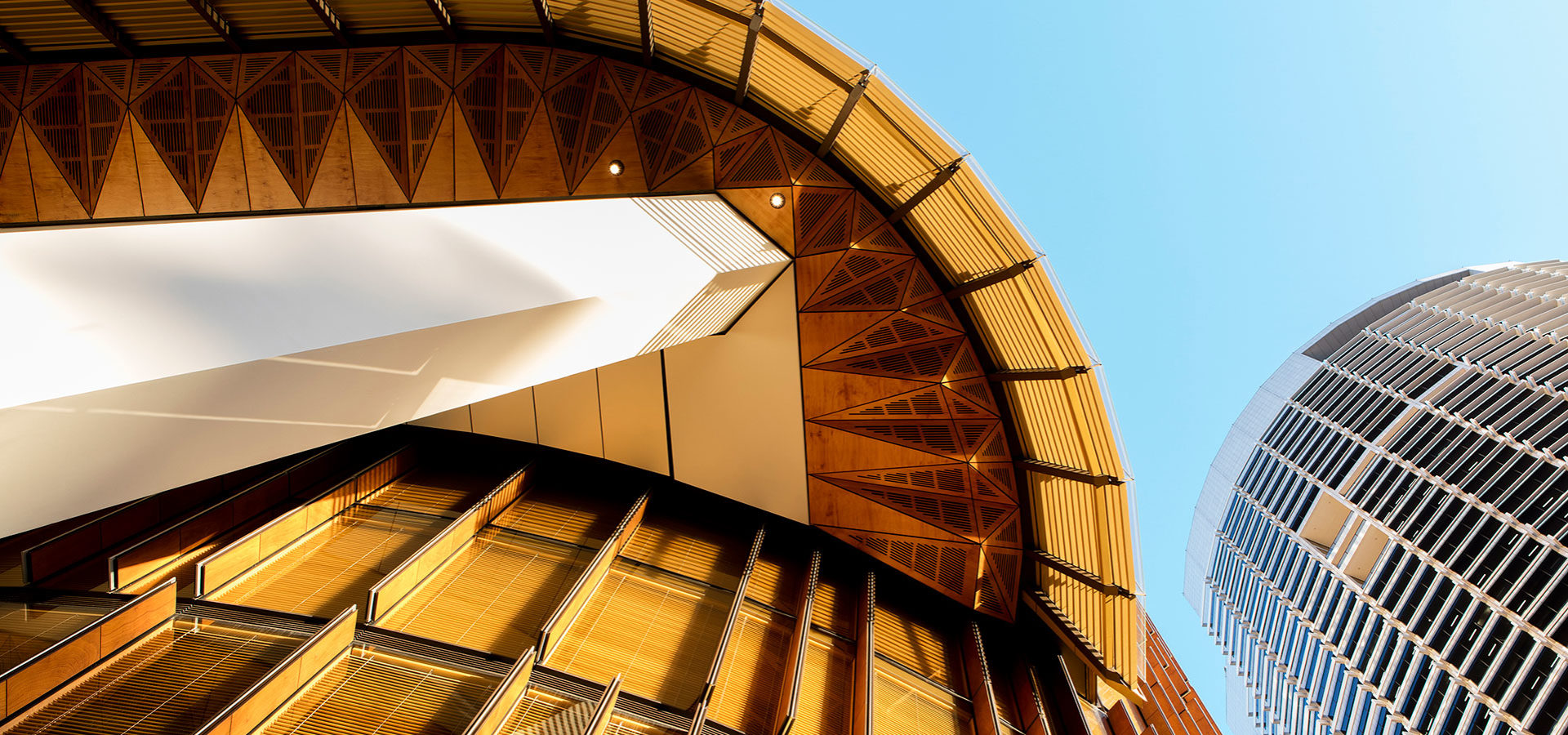

Manetti Shrem Museum by SO – IL and Bohlin Cywinski Jackson, Davis, Cali.

Aluminum Canopy manufactured by Front Inc

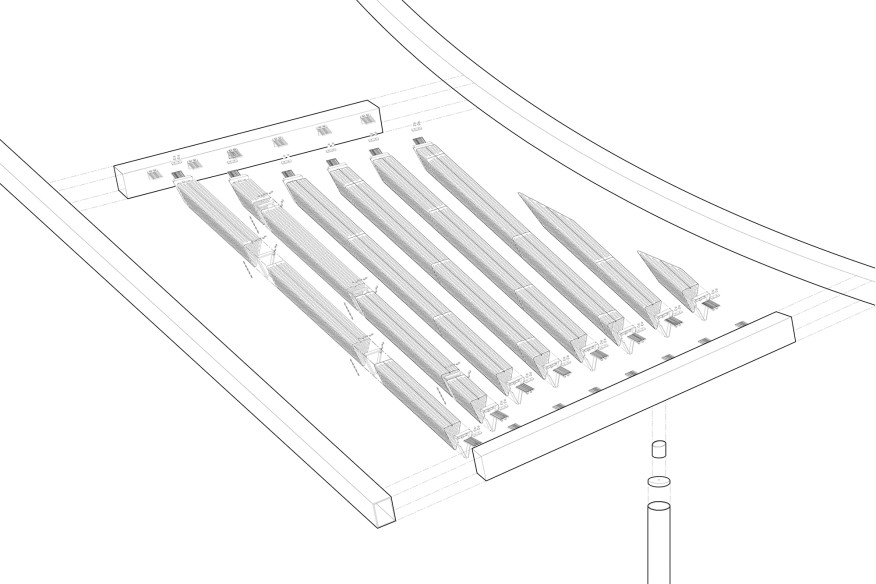

The Jan Shrem and Maria Manetti Shrem Museum of Art was designed by SO – IL and Bohlin Cywinski Jackson. Constructed in California’s Central Valley, the Manetti Shrem challenges convention as the first purpose-built museum at UC Davis. The concept was derived as “a patchwork of geometric forms that refers to the agricultural landscape and the vast horizon.” Made to be flexible and integrate with the surrounding site, the design was proposed as a new idea for the museum of the future.

As the signature element of the Manetti Shrem, the 50,000 square-foot “Grand Canopy” of perforated aluminum louvers were manufactured by Front Inc. Supported by 40 steel columns, this graceful canopy features a sloping white wave of custom marine grade aluminum. The permeable roof helps control lighting and shade to create new spaces for informal learning. Front developed the canopy for high light permeability and free spans up to 35ft. The optimized canopy was made with 1/8 inch thick aluminum with up to 40% open perforation area. The result is an integrated, elegant structure of 910 beams with unique offcuts and splice locations.

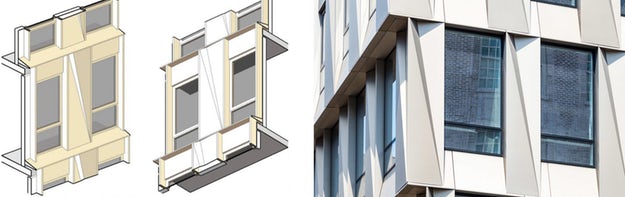

Essex Crossing by SHoP Architects, New York

Aluminum Manufactured by Walsh Glass & Metal

Fourteen stories of anodized aluminum twist along the façade of SHoP Architects’ mixed-use tower in Manhattan’s Lower East Side. Part of the Essex Crossing development, the building was made with residences in the evolving neighborhood and features some of the most coveted views of the city from all directions. As the building gets taller, it slightly steps back floor by floor. The building tapers to the west and towers to the north.

When the design process began in 2013, the torqued nature of the project became the axis of the overall vision. This was due in part because of the way the champagne-colored metal by New York manufacturer Walsh Glass & Metal could catch the light if properly shaped. When officially complete, Essex Crossing will form a compilation of buildings all featuring different cladding materials and intricate interior layouts. Its faceted metal envelope visually orients the structure upward and outward.

Harbin Opera House by MAD, Harbin, China

Metal Roof Cladding Manufactured by Shenyang Yuanda Enterprise Group

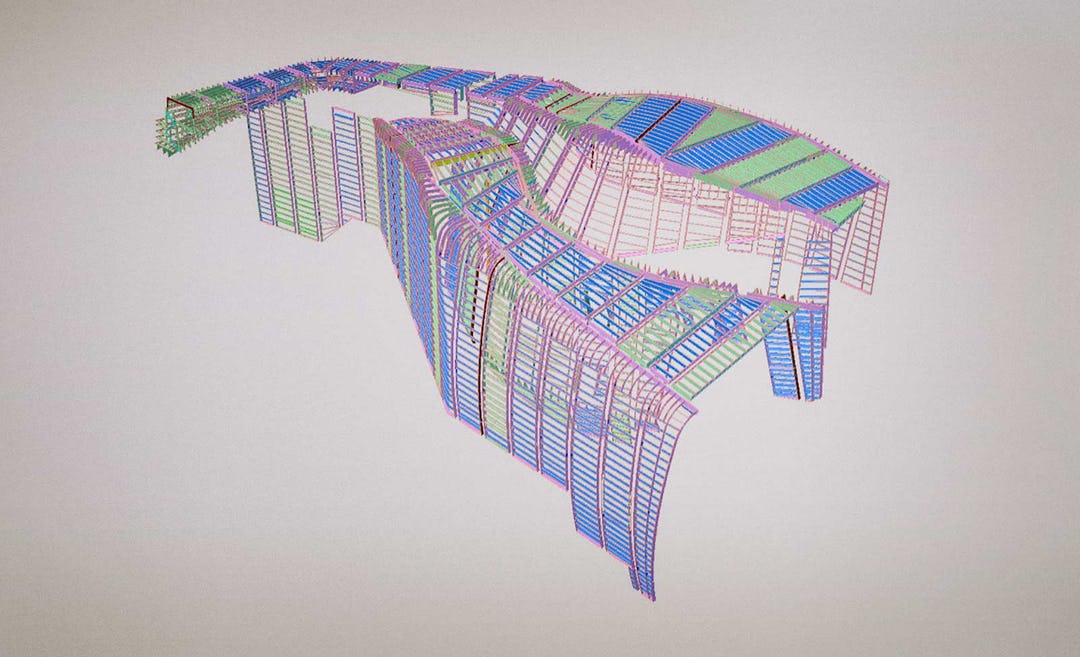

Harbin Opera House was designed by MAD as the focal point of an international competition for Harbin Cultural Island. Responding to the force and spirit of the northern city’s untamed wilderness and cold climate, the building was formed to blend in with the surrounding topography. The opera house emerged as part of a larger master plan and wetland landscape along the Songhua River. The sinuous building stands as a landmark where visitors themselves are imagined as performers. The curving, elegant structure features rehearsal halls, dressing rooms, support spaces and a pair of theaters.

MAD worked with engineers at the Beijing Institute of Architectural Design to develop the steel skeleton supporting the building’s sweeping roofscape. Visitors are encouraged to climb atop the opera house through a series of granite steps set among the building’s metal roof cladding. Visible from the ground, the rooftop terrace invites exploration and opens up to surrounding views of the Songhua river and the city skyline. The exterior cladding was manufactured by Shenyang Yuanda as a series of smooth white aluminum panels that evoke a “poetry of edge and surface, softness and sharpness.”

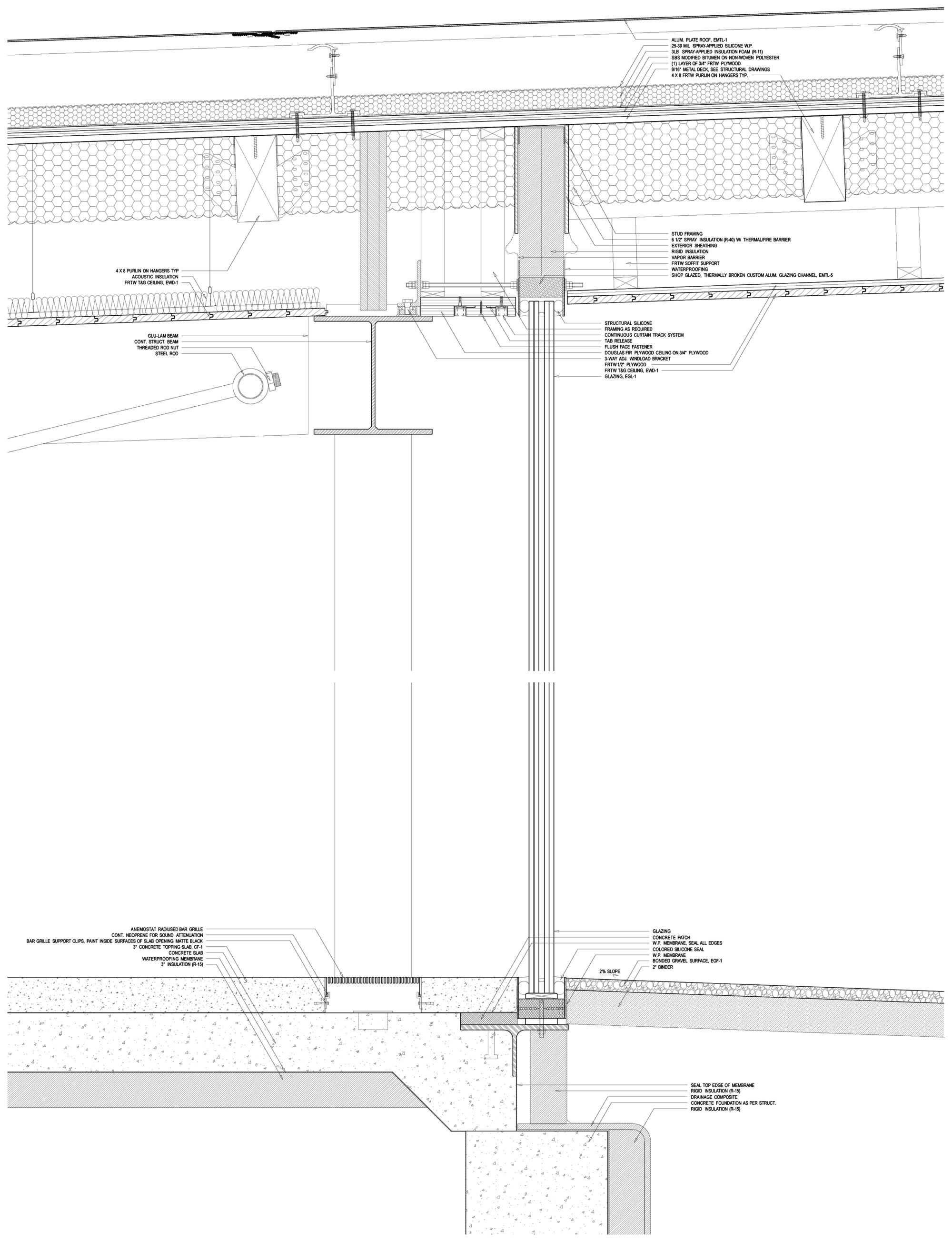

Emerson Los Angeles by Morphosis, Los Angeles, Cali.

Emerson Los Angeles by Morphosis, Los Angeles, Cali.

Custom Metal Panel Systems Manufactured by Zahner

Emerson Los Angeles was completed in 2014. Built to define the college’s identity at the center of the entertainment industry in Los Angeles, the building establishes a permanent home for the undergraduate internship program, post-graduate certificate program, and professional study programs. The design brings housing, administrative offices and instructional facilities together on an urban site.

As the most distinctive element of the project, the building features a custom metal panel systems manufactured by Zahner. These screens and panels were made to provide shade and privacy, and are composed of 17 different folded aluminum components. Zahner used 3D models to produce and fabricate the curvatures designed by Morphosis. The eight-story sunscreen was made using computational scripting to determine the final geometry that would shade the internal façades. The dynamic surface was formed through a scripting program that took into account elements like the location of the elm tree in the fifth-floor courtyard and the curvature of the classroom building.

Architects: Want to have your project featured? Showcase your work by uploading projects to Architizer and sign up for our inspirational newsletters.

Balancing Barn

Balancing Barn  Grace Farms

Grace Farms  Harbin Opera House

Harbin Opera House  Jan Shrem and Maria Manetti Shrem Museum of Art

Jan Shrem and Maria Manetti Shrem Museum of Art  Morphosis

Morphosis  Point Grey Residence

Point Grey Residence